The automotive industry is currently navigating a transformative period, driven by stringent emission regulations, the pursuit of enhanced fuel efficiency, and a global shift towards sustainable mobility solutions. In this dynamic landscape, the demand for highly optimized and durable internal combustion engines remains robust, particularly for established vehicle fleets requiring reliable replacement parts. Engine manufacturers are increasingly focusing on precision engineering, advanced material science, and rigorous quality control to meet the evolving demands of both original equipment manufacturers (OEMs) and the aftermarket. This emphasis extends to every component, ensuring seamless integration and long-term performance. Emerging trends include the adoption of lightweight alloys to reduce overall vehicle mass, advanced friction reduction technologies to improve efficiency, and sophisticated electronic control units (ECUs) for precise fuel management and emissions control. The remanufacturing sector is also experiencing significant growth, offering cost-effective and environmentally friendly alternatives to new engines, albeit with an equally rigorous focus on quality and adherence to OEM specifications. For critical components like the Engine Assembly for A16LET LLU 85 kW 1.6 L for GM OPEL, these industry trends translate into higher expectations for reliability, performance, and compliance with international standards such as Euro 5 or Euro 6 emissions regulations. The integration of advanced diagnostics and telematics further underscores the need for engines that are not only mechanically sound but also digitally intelligent, capable of communicating critical operational data for predictive maintenance and performance optimization. This holistic approach ensures that modern engine assemblies provide exceptional value and extend the operational life of vehicles, meeting the complex demands of today's automotive market.

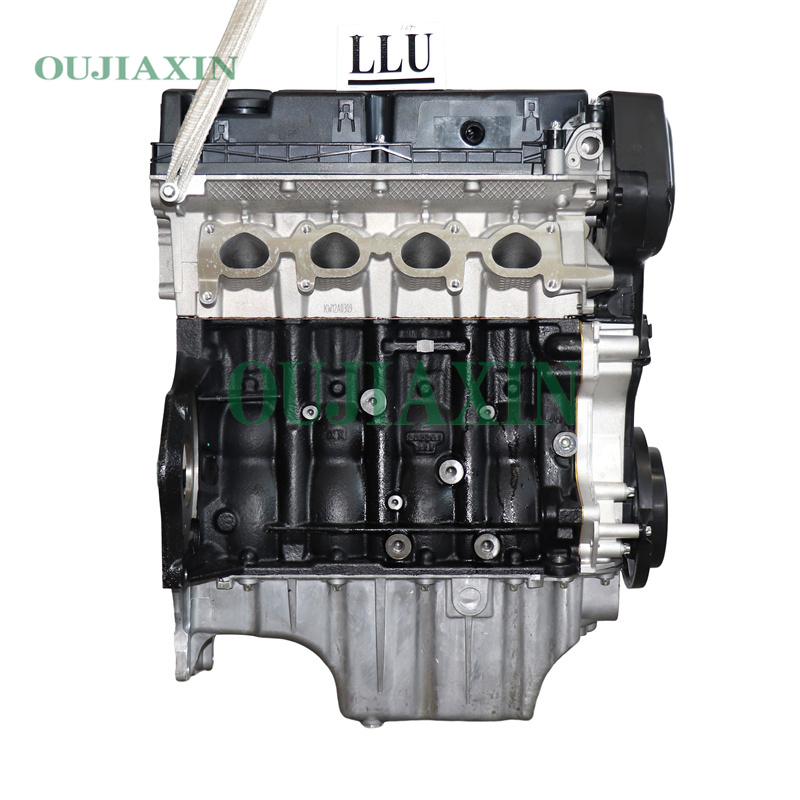

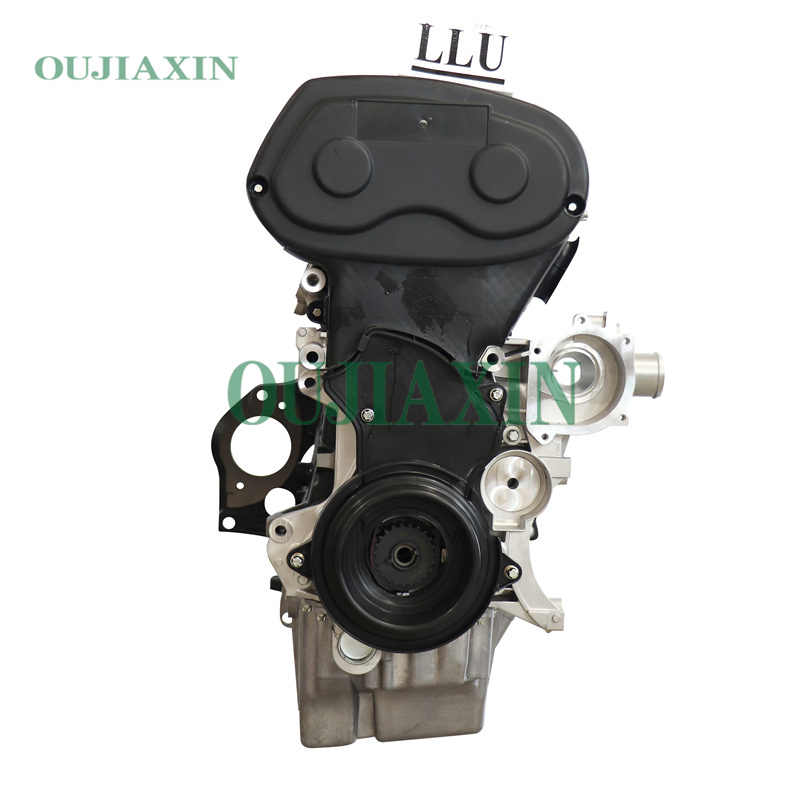

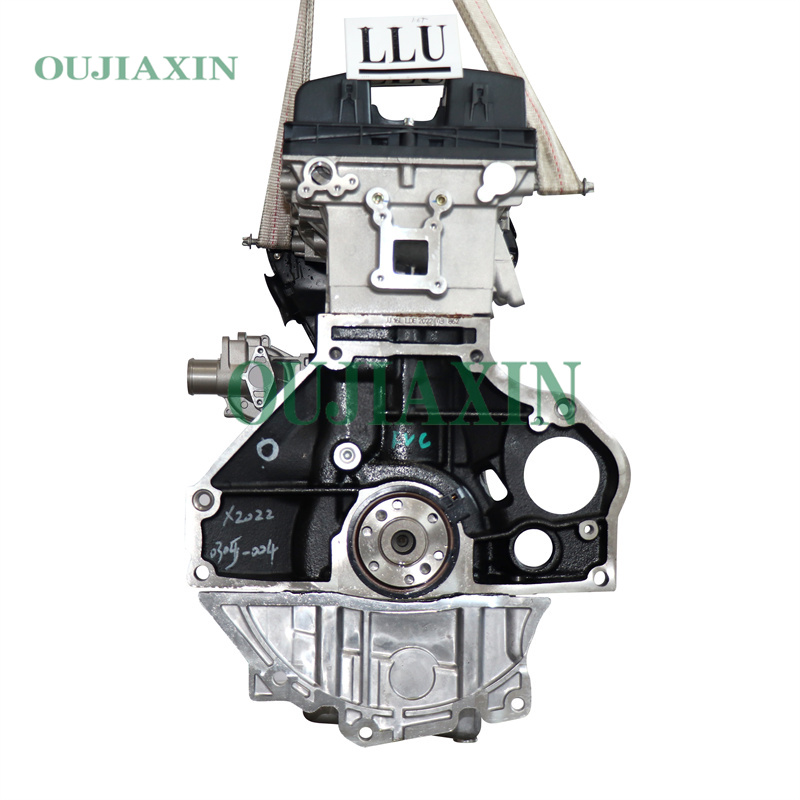

The performance and longevity of an engine assembly are fundamentally dictated by its technical specifications and the precision of its manufacturing process. For the Engine Assembly for A16LET LLU 85 kW 1.6 L for GM OPEL, rigorous adherence to design parameters is paramount. This specific engine, widely utilized in GM Opel vehicles, is a 1.6-liter turbocharged gasoline engine, identified by the A16LET and LLU engine codes, delivering 85 kW of power. Key components, including the engine block, cylinder head, crankshaft, connecting rods, and pistons, are manufactured using advanced metallurgical processes. The engine block, typically cast from high-strength aluminum alloy or gray iron, undergoes meticulous CNC machining to achieve exact tolerances for cylinder bores and bearing journals. The cylinder head, often made from aluminum, incorporates precision-machined valve seats and ports to optimize airflow and combustion efficiency. Crankshafts are generally forged from high-carbon steel for superior strength and fatigue resistance, followed by precision grinding and dynamic balancing to minimize vibrations. Pistons, forged or cast from aluminum alloys, are designed for optimal weight and thermal expansion characteristics, often featuring specialized coatings to reduce friction and wear.

Our manufacturing process for the Engine Assembly for A16LET LLU 85 kW 1.6 L for GM OPEL includes a multi-stage quality control system. Raw materials undergo spectral analysis to confirm composition. Casting and forging processes are meticulously controlled to prevent defects such as porosity or cracks. Subsequent CNC machining operations are performed with micron-level precision, followed by automated coordinate measuring machine (CMM) inspections to verify dimensional accuracy. Critical components like camshafts and valves are subjected to heat treatment processes, such as nitriding or induction hardening, to enhance surface hardness and wear resistance. Every engine assembly undergoes a comprehensive series of functional tests, including cold testing (without fuel ignition) to verify mechanical integrity and oil pressure, and hot testing (with fuel ignition) to measure power output, torque, emissions, and identify any abnormal noise or vibration. Adherence to international standards such as ISO 9001 for quality management systems and ISO/TS 16949 (now IATF 16949) for automotive production parts is fundamental. The typical service life for a well-maintained engine assembly in the automotive sector is designed to exceed 200,000 kilometers, contingent upon proper maintenance and operational conditions. This meticulous approach ensures that each assembly meets or exceeds OEM performance benchmarks and provides exceptional durability.

| Parameter | Specification |

|---|---|

| Engine Code | A16LET / LLU |

| Engine Type | 1.6L, 4-Cylinder, In-line, Turbocharged Gasoline |

| Displacement | 1598 cm³ (1.6 Liters) |

| Max Power Output | 85 kW (115 PS / 114 hp) |

| Max Torque | 155 Nm (114 lb-ft) @ 4000 rpm |

| Compression Ratio | 10.5:1 (Approximate) |

| Fuel System | Multi-Point Fuel Injection (MPI) |

| Valve Train | DOHC (Double Overhead Camshaft), 16 Valves |

| Applicable Emissions Standards | Euro 4 / Euro 5 (Model Dependant) |

| Primary Materials | Aluminum Alloy (Block, Head), Forged Steel (Crankshaft, Connecting Rods) |

| Expected Lifespan | 200,000+ km (with proper maintenance) |

The Engine Assembly for A16LET LLU 85 kW 1.6 L for GM OPEL finds its primary application in a range of GM Opel vehicles, including models such as the Astra, Meriva, and Insignia, where it serves as a robust and efficient power unit. Beyond standard passenger car applications, the inherent durability and compact design of this engine assembly make it suitable for various light commercial vehicle adaptations or specialized industrial equipment requiring a reliable 1.6-liter gasoline engine. In sectors like light logistics or mobile power generation units, the engine's consistent power output and proven reliability are significant advantages. The automotive aftermarket, including independent repair shops and fleet operators, represents a substantial application scenario, seeking high-quality replacement engines to extend the operational life of existing vehicles without incurring the prohibitive costs of new vehicle acquisition.

Key advantages of this engine assembly in typical application scenarios include its impressive fuel efficiency for its power class, largely attributable to its optimized combustion chamber design and turbocharging, which allows for smaller displacement while maintaining adequate power. This characteristic is crucial for urban fleet operators focused on reducing operational costs. Furthermore, its robust construction and selection of high-grade materials contribute to exceptional longevity, minimizing downtime and maintenance expenditure for high-utilization vehicles. In scenarios demanding resistance to harsh operating conditions, such as varying climate zones or stop-and-go city driving, the engine's design ensures consistent performance and thermal stability. While direct "corrosion resistance" isn't a primary feature of internal combustion engines as typically defined for fluid handling, the use of corrosion-resistant coatings on external components and internal oiling systems designed for superior lubrication contribute to the overall durability and integrity of the assembly in diverse environments. For instance, advanced piston ring materials and specialized cylinder bore finishes reduce wear and tear from prolonged operation. Our application cases demonstrate that vehicles fitted with our Engine Assembly for A16LET LLU 85 kW 1.6 L for GM OPEL consistently achieve extended service intervals and maintain peak performance, leading to significant long-term savings for our B2B clientele, validating its suitability across diverse operational demands.

In a competitive global market, discerning B2B clients evaluate engine assembly providers on multiple fronts: quality, performance consistency, lead times, and comprehensive support. While several manufacturers offer replacement engine assemblies, our differentiation lies in our unwavering commitment to OEM-level quality and precise compatibility for the Engine Assembly for A16LET LLU 85 kW 1.6 L for GM OPEL. Many aftermarket alternatives may cut corners on material quality or inspection protocols, leading to compromised performance or premature failure. Our products are engineered to match the original specifications, utilizing certified materials and manufacturing processes that meet or exceed industry benchmarks like ANSI standards for precision and durability. We possess decades of experience in the powertrain sector, collaborating with a network of certified suppliers and upholding stringent internal quality control, ensuring every component of the engine assembly performs as intended. Our authoritative standing is reinforced by our ISO 9001 certification and a robust track record of successful partnerships with major automotive distributors and fleet management companies across Europe and North America.

For clients with unique requirements, we offer tailored customization solutions. This can range from specific engine calibrations for varied fuel types or operational environments, to the integration of specific ancillary components required for a particular vehicle modification or industrial application. Our engineering team works closely with clients to understand their precise needs, providing expert consultation and developing bespoke solutions that maintain the core integrity and performance of the Engine Assembly for A16LET LLU 85 kW 1.6 L for GM OPEL. Our experience is showcased in numerous case studies, such as providing re-engineered assemblies for a large municipal fleet experiencing common faults with their existing engines, resulting in a 25% reduction in unscheduled maintenance over two years, or supplying specialized units for vehicles operating in extreme temperature conditions, where our enhanced cooling system components proved invaluable. Customer feedback consistently highlights our prompt delivery, superior product quality, and exceptional post-sales support as key differentiators. Our commitment to expertise, authority, and trustworthiness is not just a promise; it's a demonstrated capability evidenced by our enduring client relationships and the reliability of our products in the field.

Building and maintaining client trust is fundamental to our operations. Our commitment to providing a superior Engine Assembly for A16LET LLU 85 kW 1.6 L for GM OPEL is underpinned by a comprehensive quality assurance framework and robust customer support. Each engine undergoes a multi-point inspection and testing protocol, including dyno testing to verify power and torque output, oil pressure checks, leak detection, and sound analysis to ensure quiet and efficient operation. We proudly back our products with a comprehensive warranty, typically covering 12 to 24 months depending on application and usage, providing peace of mind to our B2B partners. This warranty covers manufacturing defects and material failures, ensuring that your investment is protected. Our delivery cycles are optimized for efficiency, typically ranging from 7 to 14 business days for standard orders, with expedited shipping options available for urgent requirements, facilitated by our established global logistics network. We understand the critical nature of minimizing vehicle downtime, and our supply chain is designed to be responsive and reliable.

Our customer support team comprises experienced technical specialists ready to assist with installation queries, troubleshooting, and post-sales service. We offer dedicated account managers for large fleet orders, ensuring personalized attention and streamlined communication. To further address common queries and build transparency, we provide a comprehensive FAQ section on our website and through our technical documentation, covering topics such as compatibility, installation best practices, and maintenance schedules for the Engine Assembly for A16LET LLU 85 kW 1.6 L for GM OPEL.