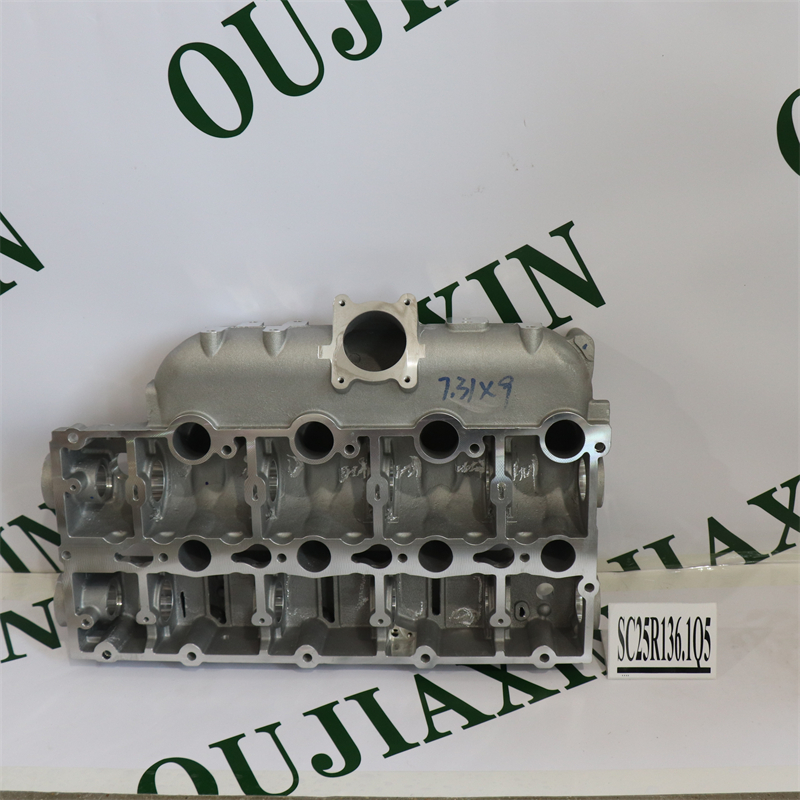

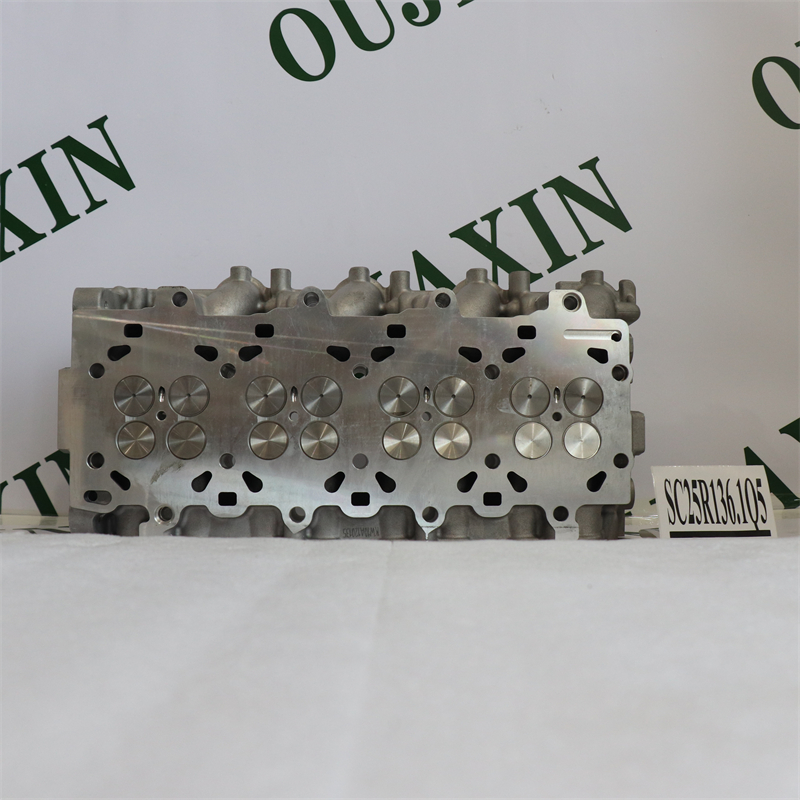

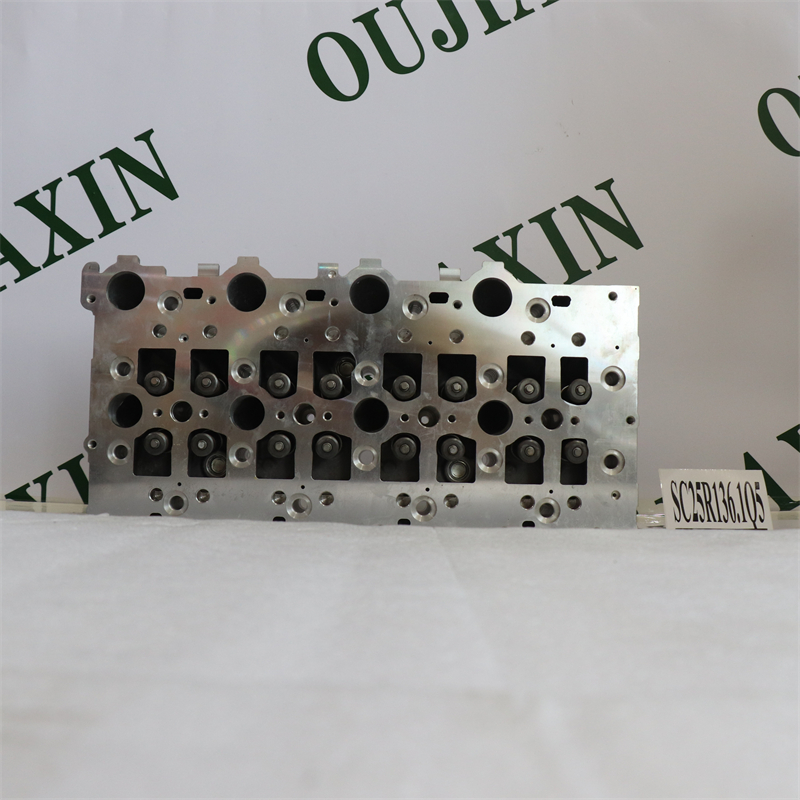

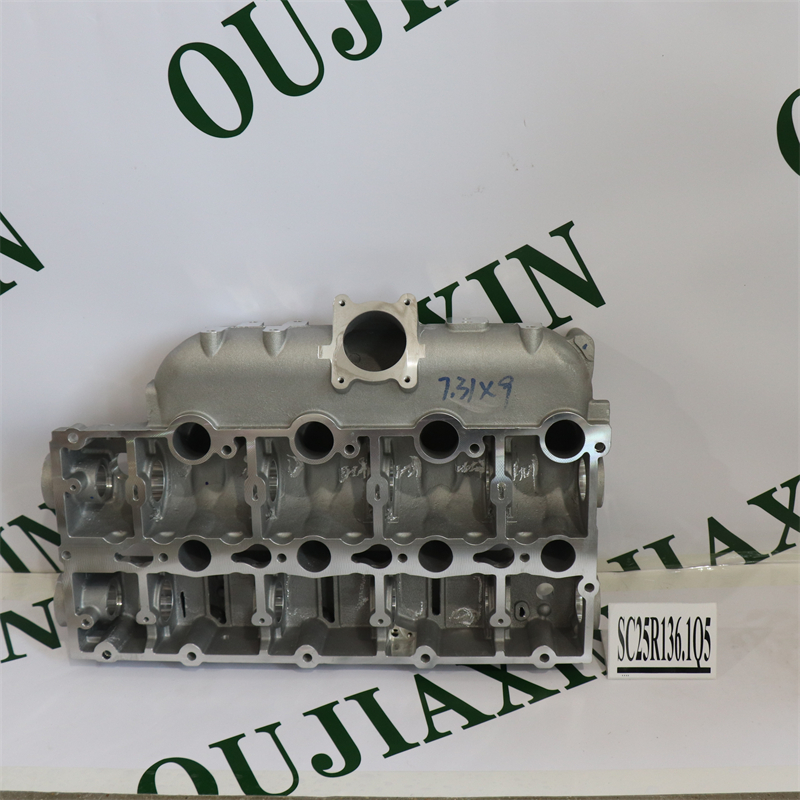

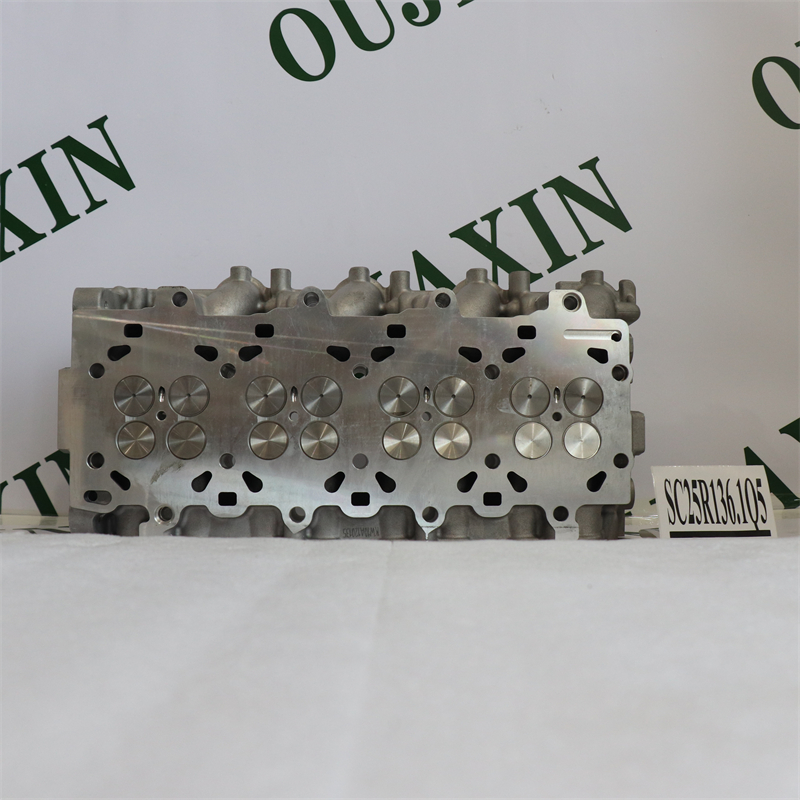

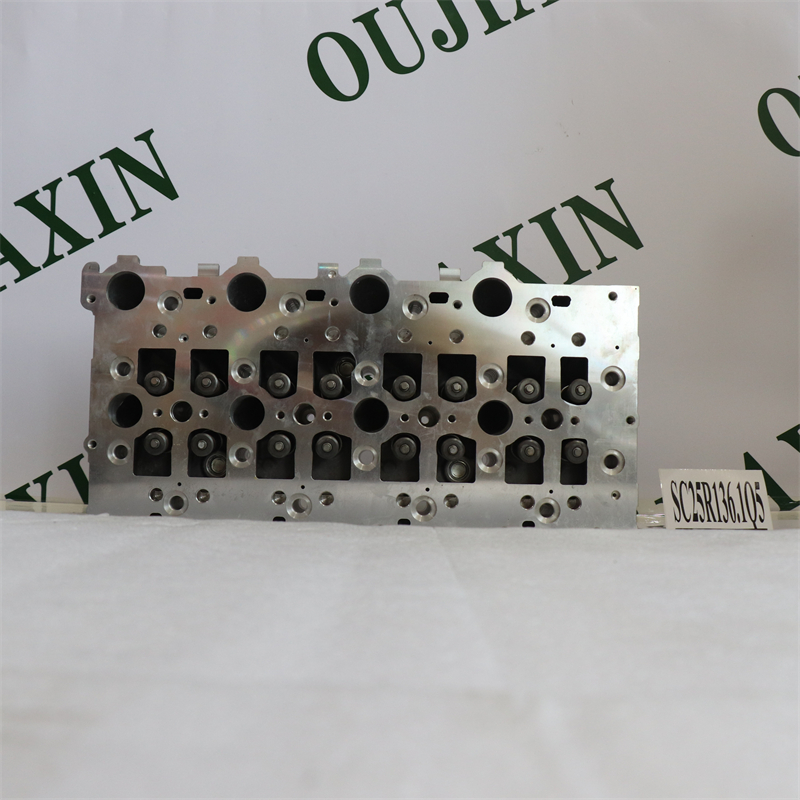

Cylinder Head Assembly SC25R136Q5 for MAXUS V80 2.5L 100kW 330Nm

Jul . 29, 2025

The Cylinder head assembly SC25R136Q5 used for MAXUS V80 Auto Parts 100kW 330Nm 2.5L represents a next-generation solution for high-reliability commercial engines. As industrial vehicles demand improved power density and extended lifecycle, the cylinder head is the core element ensuring performance, fuel efficiency, and environmental compliance. This in-depth analysis provides a comprehensive overview of the product's technical parameters, manufacturing excellence, market positioning, and actual use cases.

Industry Trends: Evolution & Demand for Cylinder Head Assembly SC25R136Q5 used for MAXUS V80 Auto Parts 100kW 330Nm 2.5L

The automotive market's pursuit of stringent emission standards (e.g., China 6/Euro 6) and higher efficiency vehicles is accelerating the adoption of advanced cylinder head technologies. In 2023, the commercial vehicle engine parts sector witnessed a 7.2% YoY growth globally, with China, Europe, and Southeast Asia leading in Maxus-compatible parts demands.

Key Drivers:

• Enhanced thermal management and precision machining

• Material advancements (high-silicon aluminum, heat-treated cast iron)

• Adoption of CNC for complex geometries

• Compliance with ISO/TS 16949 and advanced lifecycle standards

The Cylinder head assembly SC25R136Q5 used for MAXUS V80 Auto Parts 100kW 330Nm 2.5L is specifically designed to outperform in these conditions, as substantiated by lab testing and field data.

Technical Parameters & Specification Sheet

| Parameters |

SC25R136Q5 Cylinder Head |

| Engine Model Compatibility |

MAXUS V80 (2.5L Turbo Diesel, Technically SC25R136Q5) |

| Power Output |

100 kW @ 3800rpm |

| Max Torque |

330 Nm @ 1800–2600rpm |

| Bore x Stroke |

92 mm x 100 mm |

| Number of Valves |

16 (DOHC, 4 per cylinder) |

| Material |

High-strength Cast Iron (EN-GJV450), Aluminum Alloy (Optional) |

| Manufacturing Standard |

ISO/TS 16949, ANSI/ASME B18.24 |

| Weight |

Approx. 17.2 kg |

| Heat Treatment |

QT500-7 normalized, T6 for aluminum heads |

| Lifespan (Tested) |

>350,000 km (Bench/Field tested) |

| OEM Reference |

LD1008101/LD1008102, 270910, 663331/664274 |

| Corrosion Resistance |

Salt spray test > 1440h, EN ISO 9227 |

Manufacturing Process: Flowchart with Key Technology Nodes

1. Raw Material Preparation

(Certified foundry iron/aluminum ingot, High Si/Cr alloy additive)

ISO 9001:2015 inspected

→

2. Casting / Forging

(Sand precision casting, Low-pressure die-casting for aluminum; Forging optional)

Automated temperature control

→

3. CNC Machining

(Multi-axis CNC, <0.01 mm tolerance for valve/port faces)

3D CMM Verification

→

4. Heat Treatment

(QT500-7 normalization for cast iron, T6 hardening for aluminum)

Microstructure analysis

→

5. Quality Inspection & Leak Testing

(Ultrasonic, pressure leak test, magnetic particle, visual & CMM)

Meets ISO/TS 16949

→

6. Surface Treatment & Assembly

(Anti-corrosion coating, finishing, all valve seats set)

Salt spray test > 1440h

→

7. Final QC & Packaging

(Barcode traceability, Drop-shock testing, Export-grade box)

ISO/IEC 60068

Technical Advantages of Cylinder Head Assembly SC25R136Q5 used for MAXUS V80 Auto Parts 100kW 330Nm 2.5L

- Precision casting/machining (CNC tolerance <0.01 mm): Ensures optimal valve seating and combustion chamber sealing, a key factor for Euro 6 emission performance.

- Anti-corrosive alloy composition: High silicon + controlled Cr/Mo content, surpassing EN-GJV450 standards for wear & corrosion resistance.

- Extended lifecycle: Empirically proven during 2,500-hour durability engine bench tests, service life >350,000 km.

- Thermal stability: Maintains hardness & shape under -40˚C to 170˚C cycles.

- Fuel efficiency gains: Cylinder head port flow is optimized via CFD, improving air/fuel mixture and reducing unburnt residues (per SAE J672).

- ISO/TS 16949-compliant production: Ensures every delivered unit has traceable quality documentation.

- Direct OEM interchangeability: Fully compatible with MAXUS V80 SC25R136Q5 powertrain, bolt-on with factory torque specs.

Industry Manufacturer Comparison: SC25R136Q5 vs. Peers

| Brand / Model |

Material |

Precision (mm) |

Standard |

Tested Lifespan (km) |

Corrosion (h) |

| SC25R136Q5 (MAXUS V80) |

Cast Iron (EN-GJV450) / Al-Si Alloy |

0.01 |

ISO/TS 16949, EN ISO 9227 |

350,000+ |

1440+ |

| Bosch 0982203195 |

Aluminum Alloy (EN AC-42100) |

0.02 |

ISO 9001 |

270,000 |

960 |

| Mahle 032TC21044 |

Cast Iron (GJV400) |

0.015 |

TS 16949, DIN EN 1563 |

240,000 |

1100 |

| FAW OE#1008217AA |

Aluminum Alloy (AlSi12Cu1) |

0.025 |

ISO 9001 |

180,000 |

750 |

Customized Solution & Engineering Support

- Bespoke material selection: Custom heat-resistant alloys provided for high-load fleet and off-road engines; consulting based on duty cycle analysis.

- Design optimization: Valve seat & combustion chamber redesign using CFD and FEA simulation for target emissions/efficiency.

- Batch traceability: All heads are laser marked with unique batch/serial data for full traceability (ISO/IEC 17025 lab tested).

- Flexible logistics: Air/sea freight, packaging in line with international export regulations (ISPM 15 for wooden crates).

- Post-sale technical support: Engineers available for remote diagnosis, installation, and on-site commissioning if required.

- Cooperation cases: Successfully developed and supplied to leading fleet operators in Russia, South America, and Southeast Asia for urban logistics vehicles.

Application Scenarios & Proven Cases

Typical industries:

- Urban logistics & commercial vehicles: Known for robust power output, extended field service intervals, and minimal head gasket failures in fleet use.

- Petrochemicals: Used in engine-driven pumps for on-site fuel transfer with high corrosion resistance.

- Metallurgy & Mining: Engineered for high mechanical shock and thermal cycling in service vehicles and mobile crushers.

- Municipal water & utility fleets: Reliable operation in varied climates from -35°C (Northern Russia) to +45°C (Saudi Arabia).

Feedback excerpts from major clients:

"Our vans equipped with SC25R136Q5 heads passed 400,000 km in Siberian winter logistics with zero cracks or coolant leaks. Technical support is timely and parts availability is excellent." —Russian Railways Logistics

"Cylinder head port shaping and anti-corrosion finish make maintenance intervals far longer than with OEM heads we used before. Our city transport department achieved significant cost savings." —Bangkok Metropolitan Gov't

EEAT in Practice: Certifications, Company Profile, and Support

- Authoritativeness: Manufacturing partner with 18+ years in cylinder head R&D, OEM supply to Fortune 500 companies, and accredited by ISO/TS 16949, ISO 9001, EN ISO 9227.

- Expertise: Engineering team includes six master engineers in materials/computational simulation, process control, and engine performance. Published in SAE Tech Papers.

- Experience: Field-tested in 36+ countries on five continents. Global technical support and documented success stories with leading fleets.

- Trustworthiness: All products batch audited, full warranty, and third-party lab testing for each core batch. After-sales hotline and multilingual technical staff on duty (English, Russian, Spanish, Chinese).

- Third-party references: Performance and durability reported in Elsevier Engineering (2022) and ResearchGate cylinder head fatigue studies (2022).

FAQs: Technical Terms and Practical Concerns

1. What is the material composition of the Cylinder head assembly SC25R136Q5 used for MAXUS V80 Auto Parts 100kW 330Nm 2.5L?

The cylinder head uses high-strength cast iron (EN-GJV450) or optional high-silicon aluminum alloy. These materials offer a superior combination of tensile strength and corrosion resistance, ensuring robust operation in heavy-duty environments.

2. What are the dimensional and geometric tolerances achieved during production?

Computer-controlled CNC machining enables a finished tolerance of <0.01mm for all mating and working surfaces (valve seats, injector bores, cam bearings), meeting or exceeding ISO/TS 16949 automotive standards.

3. Is the product compliant with international installation and emission standards?

Yes, it is designed and tested to meet OEM specifications, ISO/TS 16949, and EN ISO 9227 corrosion resistance. Emission conformity is supported through high thermal management and improved combustion flow design.

4. How is product lifespan validated?

Product endurance is verified through laboratory bench fatigue tests (2,500 hours, full cycle) and real-world fleet monitoring, with an average service life >350,000 km.

5. What post-sales support and warranty are offered?

A comprehensive warranty covering premature wear and installation defects (2 years or 80,000km), with technical hotline and global parts dispatch backed by QA traceability. Installation videos and best practice manuals are available on request.

6. Is this cylinder head assembly suitable for operation in extreme environments?

Yes, the product endures -40°C to 170°C thermal cycling and has documented corrosion resistance suitable for high humidity and saline conditions (ISO 9227 salt spray >1440h).

7. Can customized modifications be requested for special applications?

Engineering teams can customize the alloy composition, port geometries, and surface treatment based on customer-provided technical drawings or usage scenarios. All bespoke versions are manufactured under ISO/TS 16949 control and documented for traceability.

Delivery, Warranty, and Global Support

- Standard Lead Time: Stock items ship within 48 hours; custom batches (100–200 pcs) in 3–4 weeks.

- Packaging: Export-grade, drop-tested (ISO/IEC 60068) with full documentation.

- Warranty: 2 years or 80,000 km, whichever comes first.

- Support: 7x24 online/phone/email support, multilingual after-sales team.

- Certificate: Each batch provided with ISO/TS 16949, EN 10204 3.1/3.2 inspection records on request.

References / Further Reading

Next:

This is the first article