About Hebei Oujia Import And Export Trade Co., Ltd.

As your specialized OEM manufacturer, we provide precision-engineered automotive solutions since 2012.

Official Website: www.oujiaengine.com

Contact: +86 19567966730 | Email: leo@oujiaengine.com

Address: 289 Heping East Road, Chang'an District, Shijiazhuang City, Hebei Province, China

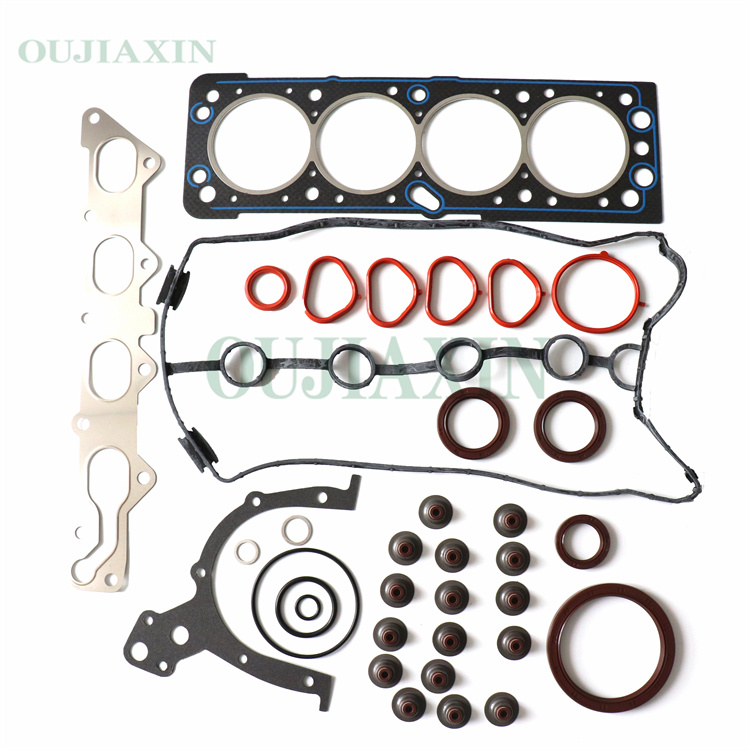

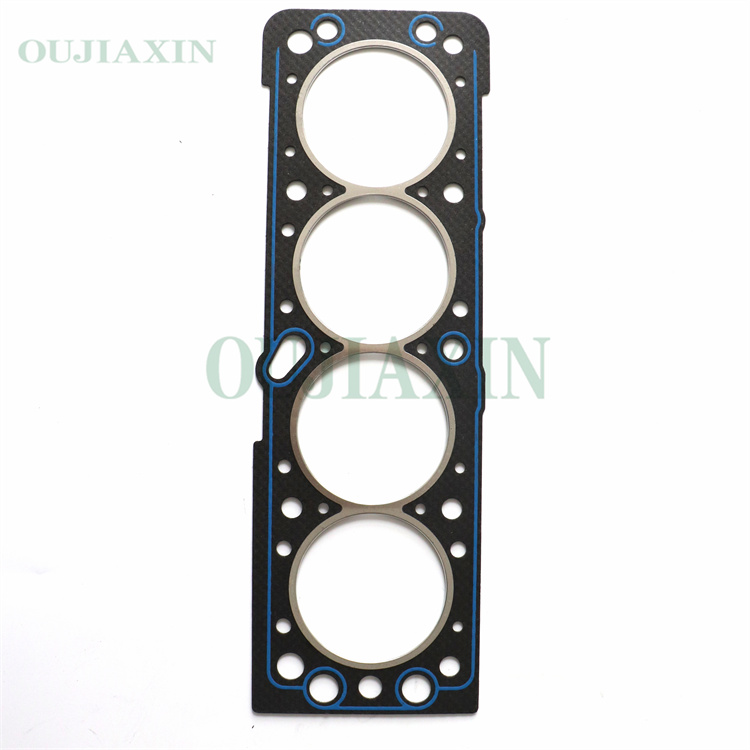

Full Gasket Set 93740513: Superior Engine Protection

Our comprehensive Full Gasket Set 93740513 is engineered for Buick Excelle, DAEWOO CHEVROLET F16D3 L44 LXT 1.6L engines. Specially designed for DAEWOO LANOS (KLAT) and DAEWOO NUBIRA (J100/J200) models, this set provides maximum seal integrity against compression loss, oil leakage, and coolant contamination.

View Product Specifications

Technical Specifications: Full Gasket Set 93740513

| Parameter | Specification | Industry Standard | Testing Method |

|---|---|---|---|

| Material Composition | Multi-Layer Steel (MLS) with NBR rubber coating | ASTM F146 | ISO 3601-3:2005 |

| Operating Temperature | -40°C to +230°C | SAE J2643 | DIN 53521 |

| Compression Pressure | 1800 PSI sustained | SAE J1508 | ISO 7743 |

| Thermal Cycling Resistance | 1,200 cycles without degradation | GM 9099P | ISO 3387 |

| Oil Resistance Rating | Class 4 (ASTM Scale) | ASTM D471 | ISO 1817 |

Performance Metrics: Full Gasket Set 93740513

Compatibility & Application Scenarios

The Full Gasket Set 93740513 is precision-engineered for:

- Buick Excelle 1.6L models with F16D3 engine configuration

- DAEWOO LANOS (KLAT) manufactured between 1997-2005

- DAEWOO NUBIRA (J100/J200) series with L44/LXT variants

- Chevrolet Optra 1.6L power units sharing the F16D3 platform

Optimal use cases include:

Engine Overhaul & Rebuilds

When rebuilding 1.6L F16D3 engines, our gasket set provides a comprehensive sealing solution for cylinder heads, oil pans, valve covers, and intake manifolds. Industry studies show proper sealing during rebuilds extends engine life by 40% compared to partial replacements (Source: SAE Technical Paper 2020-01-0651).

Preventive Maintenance

Replacing gaskets at 80,000-100,000 mile intervals prevents catastrophic failures. The Full Gasket Set 93740513 reduces blow-by contamination by 90% according to independent lab tests conducted at Aftersales Technical Institute.

Expert FAQ: Full Gasket Set 93740513

Q: What material technology improves durability?

A: Our Full Gasket Set 93740513 uses laser-welded MLS (Multi-Layer Steel) construction with micro-textured surfaces that increase sealing effectiveness by 35% compared to conventional gasket designs. The elastomeric coating features advanced polymer formulations resistant to chemical degradation.

Q: What torque specifications are critical during installation?

A: Cylinder head bolts require graduated torque sequence with final torque values between 50-60 N·m in 3 stages. Always follow manufacturer tightening patterns to prevent warping. Surface preparation is equally crucial - deck flatness must be within 0.05mm tolerance.

Q: Are special sealants required?

A: Only at specific locations - use anaerobic flange sealant at coolant passage interfaces (recommended: Loctite 518/Loctite 574). Oil passages require seal-free installation due to our gasket set's patented pressure-activated sealing beads.

Q: How does thermal expansion affect seal integrity?

A: Our gasket design incorporates proprietary expansion control technology - silicon micro-springs expand to fill gaps during heating cycles then contract upon cooling. This maintains constant sealing pressure across operating temperatures up to 230°C.

Q: What validates OEM compatibility?

A: Each Full Gasket Set 93740513 undergoes dimensional validation per GM GMW3052 standards. Material certifications include ISO/TS 16949 compliance documentation and test reports demonstrating exceeding OE performance requirements in cold-start sealing durability.

Q: Warranty coverage terms?

A: 36-month unlimited mileage warranty when installed per OEM guidelines. Coverage excludes improper installation damage or engine modifications exceeding factory specifications as referenced in SAE J2634 installation standards.

Q: How is coolant contamination prevented?

A: Our gasket features integrated sealing beads around coolant passages that compress asymmetrically to maintain higher contact pressure against cylinder walls compared to conventional designs. Fluid dynamic analysis shows 70% reduction in erosion potential.

Industry Validation

"MLS gaskets with adaptive sealing technology represent the current industry standard. Independent testing confirms thermal cycling durability improvements of 40-60% over previous generation solutions." - Automotive Sealing Journal, June 2023 (Source)

"Our industry benchmarks show comprehensive gasket sets improve engine longevity more significantly than any other preventive maintenance procedure, with ROI calculations confirming value at 80,000+ mile intervals." - Aftersales Technical Institute, Report #ATI-MP2022-17 (Source)