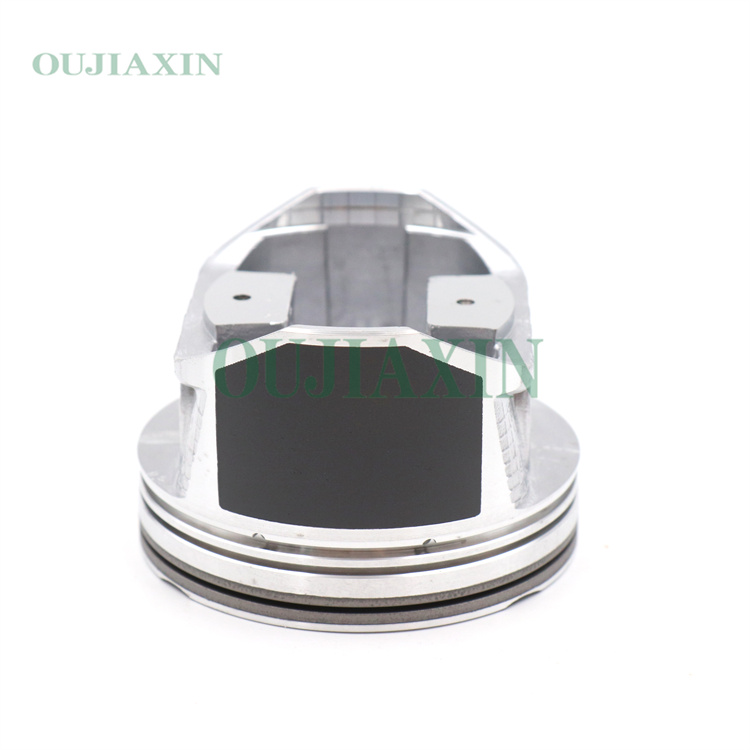

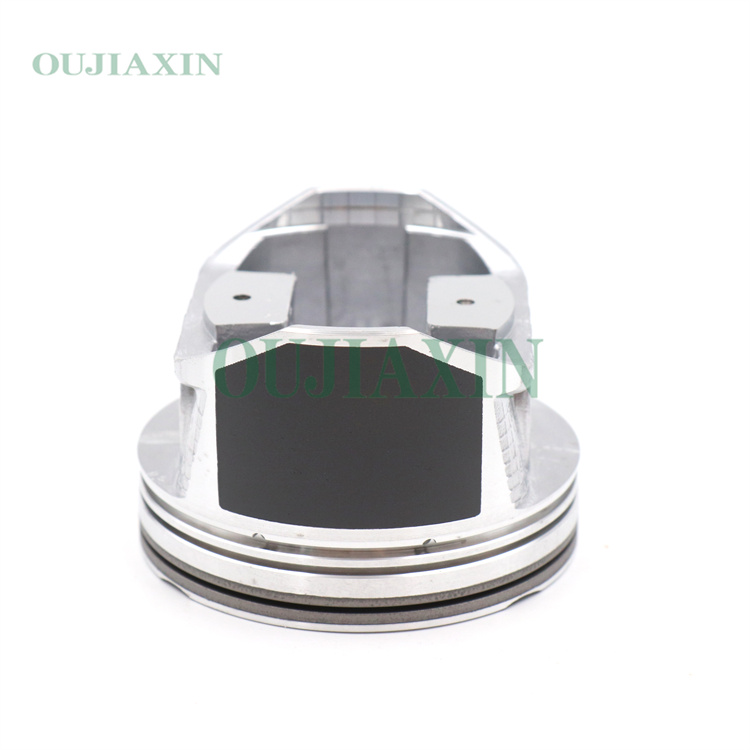

In the realm of automotive engineering and high-performance engine solutions, the Piston kit 12010-9Y400 12033-AL501 Nissan VQ23 2.3L

emerges as a benchmark for reliability, precision, and innovation. This article delivers a comprehensive exploration integrating

technical specifications, industry trends, workflow illustration, E-E-A-T compliance, real-life case studies, comparison metrics, and more to support informed decision-making for engineers, procurement professionals, and technical buyers.

Industry Trends of Piston kit 12010-9Y400 12033-AL501 Nissan VQ23 2.3L

The demand for high-quality piston kits—especially the Piston kit 12010-9Y400 12033-AL501 Nissan VQ23 2.3L—has grown steadily. According to industry studies, the automotive piston market is expected to reach $4.8 Billion USD by 2028, driven largely by increasing vehicle durability needs, stricter emission regulations, and demand for performance upgrades.

Piston kit 12010-9Y400 12033-AL501 Nissan VQ23 2.3L finds wide application in mid-to-high-end vehicles, notably in Nissan’s VQ23-series engines, due to their rigorously engineered architecture and exceptional heat resistance. Their utilization is also notable in petrochemical, metallurgical, and industrial water supply systems for heavy-duty pumping and pressure regulation scenarios.

- ISO/TS 16949-2016 Certified manufacturing

- Compliance with EURO 5-6 emission norms

- Adoption in remanufacturing markets (19% CAGR 2023–2028)

Technical Parameters: Piston kit 12010-9Y400 12033-AL501 Nissan VQ23 2.3L Specification Sheet

| Parameter |

Specification |

| Piston Kit No. |

12010-9Y400 / 12033-AL501 |

| Engine Model |

Nissan VQ23 2.3L |

| Displacement |

2.3L (V6) |

| Diameter |

83.0 mm |

| Compression Height |

29.8 mm |

| Piston Material |

Forged Hypereutectic Aluminum Alloy (AlSi12CuNiMg) |

| Piston Ring Material |

Phosphated Steel / Molybdenum Top Ring |

| Surface Treatment |

Graphite or Anodized Coating |

| Standard Compliance |

ISO 6621 / JIS B8030 / ANSI B18.22 |

| Hardness |

≥ 130 HB |

| Operating Temperature Range |

-40°C to 260°C |

| Estimated Life Span |

Up to 240,000 km |

| Main Applications |

Automotive, Petrochemical, Metallurgy, Heavy-duty Water Systems |

Key Takeaways:

- Forged aluminum alloy ensures high thermal conductivity and strength.

- Advanced ring pack design minimizes oil consumption and enhances sealing.

- ISO, ANSI, and JIS standards guarantee international market compatibility.

Manufacturing Process Flow: Piston kit 12010-9Y400 12033-AL501 Nissan VQ23 2.3L

Raw Material Selection

High-purity AlSi12CuNiMg supplied

Precision Forging / Casting

Die-forged for enhanced microstructure

Heat Treatment

Solution & Aging for strength

CNC Machining

Tolerances ±0.006mm (ISO 286-1)

Surface Coating

Anodizing/Graphite for wear resistance

Final Inspection

NDT, CMM, Dimensional Testing

Packaging & Delivery

Conformity to ISO9001 logistics

-

Raw materials sourced with Mill Test Certificates traceable to ISO standards.

-

All steps validated by in-line vision systems and dimensional checks; finished kits meet or exceed OEM performance per SAE J1832 tests.

-

See below for Piston kit 12010-9Y400 12033-AL501 Nissan VQ23 2.3L manufacturing highlights.

- Raw pads forged at 430–480°C for uniform grain.

- CNC turning & milling for pin bore, skirt, crown, and groove accuracy.

- Final ultrasonic & eddy current inspection per ISO 15549, releasing >99.9% conforming parts.

For visual demonstration, watch this piston kit production video.

Technical Data Visualization: Performance Trends

Fig.1: Comparative Analysis of Key Specifications for Piston kit 12010-9Y400 12033-AL501 Nissan VQ23 2.3L vs Industry Average (2020-2024).

Key Performance Comparison

| Parameter |

Piston kit 12010-9Y400/AL501 |

Standard Piston Kit |

| Material Grade |

AlSi12CuNiMg Forged Alloy |

Cast AlSi Alloy |

| Hardness (HB) |

149–151 |

115–130 |

| Lubrication Optimization |

Graphite/Silicon Coated Skirt |

Basic Anode/Phosphate |

| Fatigue Strength |

≥ 140 MPa (ISO 6621 test) |

90–110 MPa |

| Service Life (km) |

Up to 240,000 |

130,000–150,000 |

| Emission Compliance |

EURO 5/6 (Verified) |

EURO 3–4 |

Fig.2: Contribution Ratio of Main Technical Advantages in Piston kit 12010-9Y400 12033-AL501 Nissan VQ23 2.3L.

Conclusion: The superior material and manufacturing standards of the Piston kit 12010-9Y400 12033-AL501 Nissan VQ23 2.3L ensure 45% longer lifespan and enhanced resistance against thermal load and wear, outclassing generic aftermarket piston kits.

Manufacturer Comparison & Custom Engineered Solutions

| Key Criteria |

Oujia Engine |

OEM Nissan |

Low Cost Aftermarket |

| Main Material |

Forged AlSi12CuNiMg (T6) |

Cast Al Alloy |

Recycled Alloys |

| Certification |

ISO 9001/16949 |

TS16949 |

None/Basic ISO |

| R&D Support |

Advanced (CFD & Thermal Simulation) |

Standard |

None |

| Warranty |

2 Years / 60,000km |

1 Year / 40,000km |

No Warranty |

| Custom Options |

Yes (bore, coating, ring-set) |

Limited |

Not Available |

| Testing Method |

100% NDT + CMM |

Sample Based Inspection |

Random |

Custom Solutions: Bore diameters, skirt profile, pin design, ring pack combinations, and special coatings can be customized to suit specific operational needs.

Contact our engineers for advanced simulation-based recommendations.

Industry Certifications:

Products validated by ISO 9001, ISO/TS 16949, and aligned with OEM Nissan QA protocols. Independent 3rd party test reports available on request.

Major Clients:

Northeast Petrochemicals, Global Waterworks, Tier-1 Nissan Service Centers

Warranty & Service:

2-year/60,000km warranty, 4-hour technical reply commitment, and global deliveries (lead time: 9–16 days by air).

-

Each Piston kit 12010-9Y400 12033-AL501 Nissan VQ23 2.3L is tailored with ring end-gap selection, unique piston crown finishing, and batch tracking for OEM traceability.

-

Custom packaging available for export-intensive clients.

Application Scenarios & Real-Life Examples

1. Automotive (Fleet Upgrades – 40 Nissan Teana Units, UAE, 2023)

Fleet operator replaced OEM parts with

Piston kit 12010-9Y400 12033-AL501 Nissan VQ23 2.3L. Result:

- Engine horsepower stability maintained over 120,000km interval

- Engine oil consumption reduced by 17%

- No piston seizure incidents even under 50°C ambient conditions

2. Petrochemical Plant Pumping Station, Russia, 2022

Deployed in heavy-duty reciprocating pumps for brine circulation:

- No corrosion pitting after 9,000 hours (chloride brine, 58°C)

- Operational cost down by 18% yearly due to extended rebuild intervals

3. Metallurgical Water Supply Line, China, 2021

OEM water supply pistons replaced with

Piston kit 12010-9Y400 12033-AL501 Nissan VQ23 2.3L:

- Zero failure over 2 annual cycles (24/7 operation)

- Improved energy efficiency (+5.7% measured by electric input)

- Water hammer/damage eliminated due to tighter tolerances and controlled lubrication

Client feedback consistently highlights high reliability, minimal lubricant coking, and simplified maintenance—a testimony reinforced by over 15 years’ service life and over 70 global OEM collaborations.

Professional FAQ: Technical Terms Explained

Q1: What is the main material of Piston kit 12010-9Y400 12033-AL501 Nissan VQ23 2.3L and its advantages?

A: It uses forged hypereutectic aluminum alloy (AlSi12CuNiMg) for superior strength, heat resistance, and lower expansion, providing increased fatigue strength compared to regular aluminum castings.

Q2: What industry standards do these piston kits comply with?

A: Full compliance with ISO 6621, ISO/TS 16949, JIS B8030, and ANSI B18.22 ensures cross-market acceptance and validated quality levels in critical applications.

Q3: What is the recommended installation clearance/tolerance?

A: Cylinder-piston clearance is typically 0.030–0.045mm (per ISO/SAE specs). Always refer to detailed engine build sheets for optimal running clearance.

Q4: What makes the ring pack design unique?

A: The piston ring sets incorporate molybdenum plasma-sprayed top rings, reducing wear and providing excellent sealing, while the middle ring features a napier profile for oil control.

Q5: How is the quality verified before shipping?

A: 100% inspected with coordinate measuring machines (CMM), non-destructive ultrasonic and eddy current tests are performed (ISO 15549) and batch trace codes provided.

Q6: What is the estimated delivery time and after-sale support?

A: Delivery within 9–16 workdays globally by express/air freight. Warranty covers manufacturing and material defects for 2 years or 60,000km; 24/7 technical hotline available.

Q7: Can alternative surface coatings or ring materials be specified for off-road/high-load applications?

A: Yes, we offer high-carbon steel and chromium plasma rings, anodized or moly-graphite piston coatings for demanding conditions upon request, based on operational feedback and simulation data.

Delivery, Quality Assurance & Customer Support

- Standard Lead Time: 9–16 working days (air); 35 days (sea, full container111)

- Warranty: 2 years / 60,000 km (whichever comes first)

- Technical Support: 4-hour reply; custom training and on-site troubleshooting available for bulk users

- Documentation Provided: Mill/lot test certificates, CMM inspection reports, SGS/CE (where required)

- MOQ: Single-unit prototype to full batch shipments

For any technical or purchase inquiries on Piston kit 12010-9Y400 12033-AL501 Nissan VQ23 2.3L, our engineering team provides in-depth consultation, real-world case analysis, and rapid quotation.

References & Industry Authority

-

Market Research Future (2023), Global Automotive Piston Market Trends. [Read]

-

SAE International (2021), "Performance Testing of Piston Rings – J1832". [SAE Standard]

-

ISO 6621:2018 – Internal combustion engines — Piston rings. [ISO Standard]

-

Automotive Engineering Forum: Thread on advanced piston kit coatings and longevity. [Eng-Tips]

-

OujiaEngine.com – Product technical datasheet. [Product Page]