In the intricate world of automotive engineering, the integrity of an internal combustion engine hinges significantly on the quality and performance of its sealing components. Among these, the full gasket set stands as an indispensable assembly, a meticulously engineered collection of seals and gaskets designed to maintain crucial fluid and gas containment within various engine compartments. For the widely acclaimed Toyota 2AZ engine, known for its robust performance and prevalence in popular models like the Camry, RAV4, and Highlander, the selection of a premium Full Gasket Set 04111-28133 00140 TOYOTA 2AZ is not merely a maintenance task but a critical factor influencing the engine's long-term reliability, efficiency, and overall lifespan. Industry trends underscore a growing emphasis on enhanced material science, advanced manufacturing processes, and rigorous quality control to meet the escalating demands of modern engines, which operate at higher temperatures and pressures with tighter tolerances. These advancements are pivotal in preventing leaks of oil, coolant, and combustion gases, which can lead to severe engine damage, reduced fuel economy, and increased emissions. The shift towards multi-layered steel (MLS) gaskets, for instance, represents a significant leap forward from traditional composite materials, offering superior sealing capabilities and durability under extreme conditions. Furthermore, the automotive aftermarket demands products that not only meet or exceed OEM specifications but also offer improved resistance to thermal cycling, chemical degradation, and mechanical stress, thereby contributing to the engine's sustained optimal performance over extended periods. Ensuring the proper sealing of the cylinder head, valve covers, oil pan, intake and exhaust manifolds, and other vital interfaces prevents detrimental cross-contamination of fluids, maintains critical compression, and facilitates efficient heat dissipation, all of which are paramount for the 2AZ engine’s renowned longevity and smooth operation. The choice of a high-quality gasket set is thus an investment in the engine's future, safeguarding its internal mechanisms from wear and tear induced by fluid leaks and ensuring that every component functions in perfect harmony within its designated environment, thereby upholding the Toyota 2AZ engine's reputation for dependability and efficiency across a diverse range of applications, from daily commuting to more demanding driving conditions.

The production of a high-performance engine gasket set, such as the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ, is a testament to precision engineering, sophisticated material science, and stringent quality control. The manufacturing process typically commences with the selection of premium-grade raw materials, which are crucial for the gasket's ability to withstand extreme operating conditions. For instance, cylinder head gaskets often utilize Multi-Layer Steel (MLS), comprising several layers of specialized stainless steel or carbon steel, each embossed and coated with a thin layer of rubber or fluoro-elastomer for enhanced sealing capabilities. Other gaskets within the set may incorporate high-density graphite for exhaust manifold applications due to its excellent heat resistance, or advanced rubber composites (such as Viton, NBR, or EPDM) for oil seals and O-rings, chosen for their superior resistance to oil, coolant, and temperature fluctuations. The manufacturing journey begins with the precision cutting or stamping of these materials to exact specifications. For MLS gaskets, this involves intricate stamping dies that create the precise contours and embossments, followed by a specialized coating process—often a Viton or silicone elastomer applied via screen printing or spraying—to fill microscopic imperfections and improve conformability to engine surfaces. For components requiring higher dimensional accuracy, such as certain spacers or flanges, CNC (Computer Numerical Control) machining is employed, ensuring tolerances within micrometers. Rubber components, like valve stem seals or oil pan gaskets, are produced through injection molding or compression molding (vulcanization), where rubber compounds are heated and formed under pressure into their final shapes, followed by curing processes to achieve desired elasticity and durability. Throughout these stages, rigorous in-process quality checks are conducted, including dimensional measurements, material hardness tests, and visual inspections for defects. Post-production, each gasket and seal undergoes a battery of comprehensive testing, adhering to global automotive standards such as ISO 9001 and IATF 16949, which mandate specific quality management systems for the automotive industry. ANSI standards may also be referenced for material specifications and testing methodologies. Critical tests include thermal cycling to simulate engine operating temperatures, pressure resistance tests to verify sealing integrity under varying engine loads, and chemical compatibility tests to ensure longevity against engine fluids. The expected service life of a Full Gasket Set 04111-28133 00140 TOYOTA 2AZ is directly correlated with these meticulous manufacturing and testing protocols, typically aligning with or exceeding OEM specifications, often ranging from 100,000 to 150,000 miles under normal operating conditions. This robust engineering makes these gasket sets indispensable across a multitude of industries beyond just automotive repair. In sectors like petrochemicals, where stationary engines are vital for pumping and power generation, or in metallurgy, where heavy machinery relies on robust internal combustion engines, and even in specialized applications within water supply and drainage systems requiring reliable pump engines, the principles of durable sealing for fluid and gas containment are equally critical. For instance, in a large-scale industrial pump, a high-quality gasket set ensures minimal energy loss due to leaks, contributing to energy efficiency. In corrosive environments typical of petrochemical plants, the material selection and coating resist chemical degradation, offering anti-corrosion advantages. This comprehensive approach to manufacturing, from raw material to final testing, ensures that the gasket set performs optimally in demanding scenarios, safeguarding operational integrity and extending the lifespan of vital machinery across diverse industrial landscapes.

Understanding the technical parameters of the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ is paramount for professionals involved in engine maintenance, overhaul, and remanufacturing. These specifications are not merely numbers; they represent the precise engineering and material science optimized for the unique operational dynamics of the Toyota 2AZ engine. The paramount component, the cylinder head gasket, is typically of the Multi-Layer Steel (MLS) type, designed to withstand the extreme pressures and temperatures of combustion, which can exceed 1500 psi and 1000°C (1832°F). The number of layers (e.g., 3-5 layers) and their specific embossments are critical for maintaining a hermetic seal against combustion gases and coolant/oil passages. The primary material for MLS layers is often high-grade stainless steel (e.g., SUS301 or SUS304) for its excellent strength and corrosion resistance, coated with FKM (Fluoroelastomer) or silicone rubber for enhanced sealing under dynamic thermal cycling. The temperature range for critical components like valve stem seals typically extends from -40°C to +200°C (-40°F to +392°F), utilizing specialized Viton or ACM (Polyacrylate Rubber) for superior oil and heat resistance. Oil pan gaskets and valve cover gaskets, often made of molded rubber or cork-rubber composites, are designed to maintain integrity against engine oil and provide flexibility for varied sealing surfaces. The pressure resistance for various seals varies; for instance, crankshaft and camshaft seals are engineered to withstand internal oil pressure while minimizing friction, often utilizing PTFE (Polytetrafluoroethylene) or ACM lip seals. OE (Original Equipment) compatibility is a fundamental parameter, ensuring that the gasket set meets or surpasses the specifications of the gaskets originally installed by Toyota, guaranteeing a perfect fit and function without modification. This includes precise bolt hole alignment, port geometries, and thickness specifications to maintain correct engine compression ratios and valvetrain clearances. The dimensional accuracy, particularly thickness and bore diameter, is subject to extremely tight tolerances (e.g., +/- 0.05 mm) to ensure optimal sealing compression. Material hardness (e.g., Shore A durometer for rubber components) is another crucial parameter, influencing the gasket's ability to conform to surface imperfections and resist wear. The durability is assessed by extensive fatigue testing, simulating millions of engine cycles to predict actual service life. Corrosion resistance of all metallic components to engine coolants and oils, often containing various additives, is rigorously tested. Furthermore, the overall completeness of the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ, including all necessary O-rings, seals, and specialized gaskets for a complete engine overhaul, ensures that technicians have every component required for a comprehensive and reliable repair. These meticulous specifications collectively contribute to preventing common engine issues such as oil leaks, coolant leaks, and compression loss, which directly impact fuel efficiency, exhaust emissions, and engine longevity. By adhering to and often exceeding these critical parameters, a high-quality gasket set guarantees the 2AZ engine operates at its intended performance levels, safeguarding its intricate internal mechanisms from the relentless forces of combustion and friction, and thereby extending the operational lifespan and reliability of the vehicle.

The versatility and widespread adoption of the Toyota 2AZ engine across numerous vehicle platforms mean that the demand for a reliable Full Gasket Set 04111-28133 00140 TOYOTA 2AZ extends across a broad spectrum of applications and industries. Primarily, this gasket set is indispensable in the automotive repair and maintenance sector, serving independent workshops, franchised dealerships, and mobile mechanics specializing in Toyota vehicles. These entities rely on high-quality gasket sets for routine engine rebuilds, cylinder head repairs, and major engine overhauls prompted by issues such as overheating, head gasket failure, or high mileage wear. Beyond general repair, the automotive remanufacturing industry is a significant consumer. Companies specializing in remanufactured engines painstakingly disassemble, inspect, and rebuild core engines to meet or exceed OEM specifications. A comprehensive full gasket set is critical for ensuring these remanufactured units deliver "like-new" performance and reliability, extending the life cycle of the engine block and components. Fleet maintenance operations, ranging from taxi companies to logistics firms that utilize Toyota vehicles, also represent a key application area. For these businesses, minimizing vehicle downtime and ensuring long-term operational efficiency are paramount. Proactive replacement of aging gasket sets during scheduled major maintenance intervals or promptly addressing leaks with a quality replacement significantly reduces costly breakdowns and ensures fleet readiness. Furthermore, niche markets such as vehicle modification and performance tuning, while less common for the 2AZ than some other engines, still benefit from the availability of robust sealing solutions. When internal engine components are upgraded to handle increased power outputs or different operating conditions, the integrity of the seals becomes even more critical, often necessitating gaskets that can endure higher stresses. The advantages of employing a premium Full Gasket Set 04111-28133 00140 TOYOTA 2AZ are multifaceted. Firstly, it offers superior leak prevention, eliminating the risk of oil, coolant, or combustion gas leaks that can lead to catastrophic engine failure or gradual degradation. This directly translates to significant energy efficiency improvements, as a well-sealed engine maintains optimal compression for complete combustion and prevents parasitic losses from escaping fluids. Secondly, enhanced anti-corrosion properties of advanced materials within the gasket set protect vital engine components from the corrosive effects of aggressive coolants and lubricants, extending the lifespan of the engine itself. Thirdly, the robust design and precise fit contribute to noise reduction by ensuring proper sealing of intake and exhaust manifolds, preventing air or exhaust leaks that can cause unwanted engine noise and vibrations. Lastly, by restoring the engine to its optimal sealing integrity, the gasket set directly contributes to reduced exhaust emissions, aiding vehicles in passing stringent environmental inspections and contributing to a cleaner environment. The broad applicability and tangible benefits underscore why investing in a high-quality full gasket set is not merely a repair cost but a strategic decision for sustaining the performance, reliability, and economic viability of Toyota 2AZ-powered vehicles across diverse professional and industrial contexts.

The global market for automotive engine gaskets is a highly competitive landscape characterized by a blend of established OEM suppliers, reputable aftermarket manufacturers, and emerging players. Understanding this dynamic environment is crucial for making informed procurement decisions, especially concerning a critical component like the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ. Leading manufacturers distinguish themselves primarily through several key factors: extensive research and development capabilities, which drive innovation in material science and sealing technologies; stringent quality control processes that ensure consistent product performance and reliability; and sophisticated manufacturing techniques that achieve micron-level precision. OEM suppliers, while setting the benchmark, often provide products at a premium, whereas top-tier aftermarket manufacturers aim to offer equivalent or superior quality at more competitive price points, often leveraging economies of scale and specialized production lines. For instance, some manufacturers excel in Multi-Layer Steel (MLS) gasket technology, utilizing proprietary embossing patterns and coating formulations to enhance sealing under dynamic thermal cycles. Others might specialize in advanced rubber compounds for oil seals, developing materials with extended temperature resistance and improved chemical compatibility. Factors such as global distribution networks, technical support, and warranty policies also play a significant role in a manufacturer's market position and perceived value. Companies with robust R&D pipelines often introduce improvements such as anti-friction coatings on oil seals or redesigned gasket geometries to address known OEM weaknesses, effectively providing an "upgrade" over original specifications. When evaluating providers of the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ, it is imperative to consider their certifications (e.g., IATF 16949, an automotive-specific quality management system standard, is often more relevant than general ISO 9001 for component manufacturers), their experience with Toyota engine platforms, and their ability to provide comprehensive, full-service solutions. The market is also seeing increasing demand for "greener" solutions, including asbestos-free materials and manufacturing processes with reduced environmental impact, which forward-thinking manufacturers are embracing. Our competitive advantage in the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ segment stems from our unwavering commitment to these principles. We combine precision engineering with advanced material selection, ensuring that every gasket and seal in our set not only meets but often exceeds OEM specifications. Our vertically integrated manufacturing process allows for meticulous control over every stage, from raw material sourcing to final packaging, guaranteeing unparalleled consistency and performance. Furthermore, our focus on continuous improvement, driven by feedback from professional mechanics and remanufacturers, ensures that our products evolve with the demands of modern engine technology. This dedication positions us as a reliable partner for businesses seeking uncompromising quality and long-term value in their automotive component procurement.

While standard replacement parts cater to the vast majority of needs, there are specific scenarios in the automotive and industrial sectors where off-the-shelf solutions may not suffice. This is where the capability to provide custom gasket solutions and engage in engineering partnerships becomes invaluable, especially for components as critical as the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ. Customization is often sought for niche applications, classic car restoration projects requiring specific vintage material compositions, or for performance applications where engine modifications demand gaskets capable of handling higher boost pressures, increased thermal loads, or non-standard fluid compositions. For instance, a racing team might require a specialized MLS head gasket with a unique bore size or compression ratio, or a fleet operator might need specific chemical resistance for a custom fuel blend. The process for developing a custom gasket solution typically begins with a detailed consultation to understand the precise operational parameters, environmental conditions, and material requirements. Our engineering team, leveraging expertise in sealing dynamics and advanced materials, then collaborates with the client to design a prototype. This involves CAD modeling, material selection (e.g., exploring advanced composites, specialized elastomers, or exotic metal alloys), and rapid prototyping techniques. Subsequent stages include rigorous laboratory testing, such as thermal cycling, pressure testing, and chemical compatibility tests, to validate the design and material performance under simulated real-world conditions. The benefits of such engineering partnerships are manifold. Firstly, they ensure an exact fit and optimal performance for highly specialized or non-standard applications, eliminating the compromises often associated with adapting generic parts. Secondly, it provides access to cutting-edge material science and manufacturing techniques that might not be available to smaller operations. Thirdly, it fosters innovation, as challenges presented by unique applications often lead to the development of new solutions that can eventually benefit a broader market. A compelling case study illustrates this: a client in the marine engine remanufacturing sector, specializing in adapted Toyota 2AZ engines for saltwater environments, faced persistent issues with standard oil seals degrading prematurely due to saline exposure and elevated humidity. Through an engineering partnership, we developed custom Viton-based oil seals with enhanced resistance to saltwater corrosion and hydrolysis, tailored specifically for their application. This bespoke solution not only eliminated the recurring seal failures but also extended the service interval of their remanufactured marine engines by over 30%, resulting in significant cost savings and improved customer satisfaction. This example underscores how collaborative engineering and tailored solutions for the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ, or individual components within it, can unlock new levels of performance and reliability beyond the scope of mass-produced parts, solidifying long-term strategic relationships built on trust and technical excellence.

In today's highly competitive B2B landscape, particularly within the automotive aftermarket, demonstrating adherence to Google's (Expertise, Experience, Authoritativeness, Trustworthiness) framework is not just an SEO best practice but a fundamental requirement for building lasting client relationships. Our offering of the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ is meticulously built upon these four foundational pillars, ensuring our clients receive not just a product, but a comprehensive solution backed by unparalleled quality and support.

Expertise: Our team comprises seasoned engineers and automotive specialists with decades of collective experience in sealing technology and engine dynamics. This deep-seated expertise allows us to not only manufacture gaskets but to understand the intricate nuances of the Toyota 2AZ engine's design, its common failure points, and the precise demands placed on its sealing components. We are fluent in the technical terminology, from thermal expansion coefficients of MLS gaskets to the durometer hardness of Viton oil seals, enabling us to provide insightful technical support and product recommendations. Our continuous investment in R&D ensures we stay at the forefront of material science and manufacturing innovations, translating into superior product performance. We regularly conduct internal seminars and external training to keep our knowledge base current with the latest advancements in engine technology and gasket design, ensuring our solutions are always optimized for contemporary engine architectures and operational demands. This commitment to ongoing learning and development permeates our entire organization, from the design phase to customer service, allowing us to accurately diagnose sealing challenges and propose effective, long-lasting solutions.

Experience: Our extensive track record in supplying high-quality automotive gasket sets speaks volumes about our practical experience. We have successfully served thousands of clients, ranging from individual repair shops to large-scale fleet operators and engine remanufacturing facilities, each relying on our Full Gasket Set 04111-28133 00140 TOYOTA 2AZ for critical engine overhauls. We've gathered invaluable feedback from diverse usage scenarios, from extreme climate operations to high-mileage commercial vehicle applications, which continually informs our product refinement process. One notable success story involves a major taxi fleet operating Toyota Camry vehicles with 2AZ engines. They faced recurrent head gasket failures with previous aftermarket suppliers, leading to significant vehicle downtime. Upon switching to our gasket sets, they reported a dramatic reduction in unscheduled engine repairs, extending the service life of their engines by an average of 50,000 miles before requiring major intervention. This hands-on experience in addressing real-world challenges and delivering tangible improvements underscores our practical know-how and commitment to long-term reliability. Our history is dotted with similar success stories where our products have proven their mettle under the most demanding operational conditions.

Authoritativeness: Our position as an authoritative supplier is underpinned by our adherence to stringent international quality standards and industry recognition. We hold ISO 9001 certification for our quality management systems, demonstrating a consistent commitment to meeting customer and regulatory requirements. More critically for automotive components, our manufacturing processes for the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ are certified under IATF 16949, the automotive industry's most widely used international standard for quality management. This certification signifies our dedication to defect prevention and continuous improvement, reducing waste in the supply chain. We also regularly commission independent third-party testing for our products, verifying material integrity, sealing performance, and durability against industry benchmarks. Our partnerships with leading automotive parts distributors and engine rebuilders further solidify our authoritative standing in the market. We openly share test data and performance reports, offering transparent insights into our product capabilities. Our long-standing tenure in the industry, spanning over a decade of dedicated service, coupled with a robust portfolio of successful projects and strategic collaborations, cements our reputation as a trusted authority in engine sealing solutions.

Trustworthiness: Trust is the cornerstone of any successful B2B relationship. We foster trustworthiness through transparent business practices, robust product support, and clear commitments. Our comprehensive warranty policy for the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ provides clients with peace of mind, demonstrating our confidence in product quality. We offer clear and predictable delivery schedules, supported by efficient logistics, ensuring timely arrival of critical components. Our dedicated customer support team is readily available to address inquiries, provide technical assistance, and resolve any issues promptly and effectively. The provision of detailed technical specifications, installation guides, and troubleshooting tips further empowers our clients. We maintain an open line of communication, actively seeking feedback to continually refine our services and products. Our commitment to ethical business conduct, fair pricing, and reliable after-sales service reinforces our trustworthiness, making us a dependable partner for all engine sealing needs. This commitment extends to our comprehensive FAQ section, warranty information, and direct customer support channels, all designed to build and maintain the highest level of trust with our valued clientele.

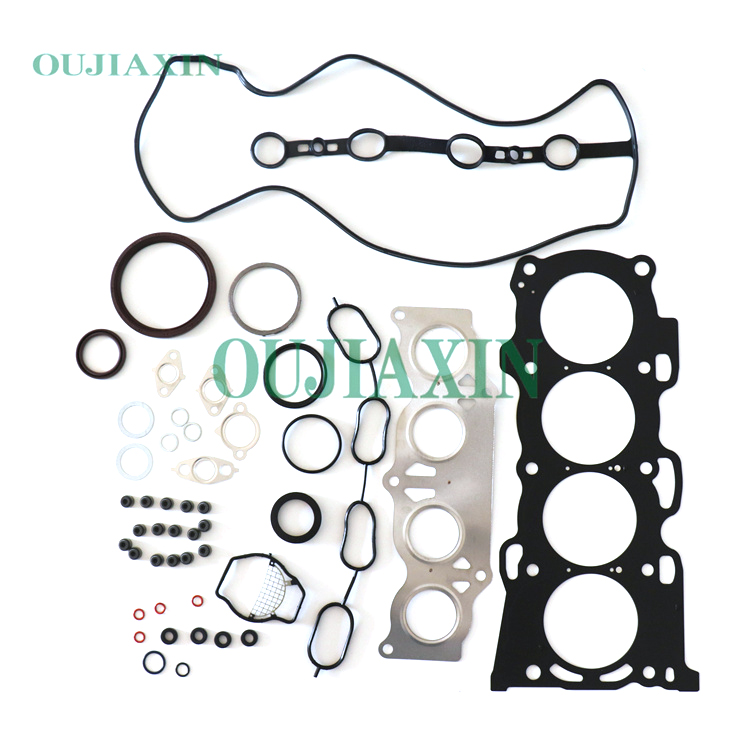

A comprehensive Full Gasket Set 04111-28133 00140 TOYOTA 2AZ typically includes all the necessary gaskets and seals required for a complete engine overhaul. This commonly encompasses the cylinder head gasket (often MLS type), valve cover gaskets, intake and exhaust manifold gaskets, oil pan gasket, front and rear crankshaft seals, camshaft seals, valve stem seals, timing cover gasket, water pump gasket, thermostat housing gasket, and various O-rings and small seals for components like injectors, spark plugs, and coolant passages. The exact contents may vary slightly between manufacturers but are designed to provide all the essential sealing components for rebuilding the 2AZ-FE engine from the block up, ensuring a complete and leak-free assembly. It's crucial to verify the specific contents listed by the manufacturer to ensure it meets the requirements of your particular engine repair or rebuild project, thereby avoiding the need for separate purchases of missing seals.

The Toyota 2AZ engine, while highly reliable, operates under significant thermal and mechanical stresses. A high-quality Full Gasket Set 04111-28133 00140 TOYOTA 2AZ is critical because it ensures optimal sealing of combustion gases, engine oil, and coolant, preventing detrimental leaks and maintaining proper engine compression. Inferior gaskets can lead to common issues such as overheating, oil consumption, coolant contamination, reduced power output, and increased emissions. Using precision-engineered gaskets made from advanced materials, such as Multi-Layer Steel (MLS) for head gaskets or Viton for oil seals, guarantees superior thermal stability, chemical resistance, and long-term durability, directly impacting the engine's lifespan and operational efficiency. Investing in quality prevents costly future repairs and maintains the engine's original performance characteristics, preserving its renowned reliability and fuel economy.

Key material considerations for the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ are paramount for performance and longevity. For the cylinder head gasket, Multi-Layer Steel (MLS) is preferred due to its ability to withstand extreme combustion pressures and temperatures, offering superior elasticity and crush resistance compared to older composite types. Exhaust manifold gaskets often use high-density graphite or perforated steel laminate (PSL) for their excellent heat resistance (up to 1100°C) and ability to conform to irregular surfaces. For oil seals (crankshaft, camshaft, valve stem), Viton (FKM) and ACM (Polyacrylate Rubber) are standard choices due to their exceptional resistance to engine oils, synthetic lubricants, and high temperatures. Valve cover and oil pan gaskets may utilize molded rubber (e.g., silicone, NBR) or cork-rubber composites, chosen for their sealing properties against oil and lower temperatures. The precise selection of each material within the set ensures optimal performance and durability for its specific application within the engine's diverse sealing requirements.

ISO 9001 is a general international standard for quality management systems, ensuring that a manufacturer has processes in place to meet customer and regulatory requirements consistently. IATF 16949, on the other hand, is a more stringent, automotive-specific quality management standard, built upon ISO 9001, but with additional requirements for the design, development, production, installation, and servicing of automotive-related products. For the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ, a manufacturer adhering to IATF 16949 implies a higher level of commitment to defect prevention, reduction of variation and waste, and continuous improvement throughout the entire production process. This results in products that are consistently manufactured to the highest standards of reliability and performance, giving B2B clients greater assurance of quality and fitment for critical engine components. It signifies that the manufacturer has robust systems for process control, risk management, and supplier management.

Our typical delivery timeframe for bulk orders of the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ varies based on order volume, current stock levels, and shipping destination. For standard orders, we generally aim for dispatch within 3-5 business days, with transit times depending on the chosen shipping method (e.g., air freight for faster delivery, sea freight for cost efficiency). We work closely with trusted logistics partners to ensure timely and secure delivery globally. For very large or recurring orders, we can establish customized fulfillment schedules and inventory management solutions. In terms of support, we offer comprehensive pre-sales and after-sales assistance. This includes technical consultation to ensure correct product selection, detailed installation guidance, troubleshooting support, and a robust warranty program. Our dedicated customer service team is available via phone and email to address any inquiries or concerns promptly, reinforcing our commitment to client satisfaction and long-term partnership. We prioritize transparent communication regarding lead times and provide tracking information for all shipments.

Choosing the right sealing components for a critical engine like the Toyota 2AZ is not just about the initial purchase; it’s an investment in the long-term reliability and performance of the vehicle. Our commitment to quality for the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ extends far beyond the point of sale, encapsulated by our robust warranty policy and comprehensive customer support infrastructure. We stand behind the engineering excellence and manufacturing integrity of every gasket set we produce. Our standard warranty covers defects in materials and workmanship for a period of 12 months or 12,000 miles (whichever comes first) from the date of purchase, ensuring peace of mind for our B2B clients. In the unlikely event of a product issue attributable to manufacturing defects, we commit to prompt replacement or credit, subject to our standard terms and conditions. This policy is designed to instill confidence and reflect our belief in the durability and performance of our products under normal operating conditions when installed correctly by qualified professionals.

Beyond the warranty, our customer support is a cornerstone of our service offering. We understand that in the fast-paced automotive repair and remanufacturing industries, quick and accurate technical assistance is paramount. Our dedicated support team comprises experienced technical advisors who possess in-depth knowledge of our products and engine sealing principles. They are available to provide guidance on product selection, offer installation best practices, and assist with troubleshooting complex issues. Whether you have a question about material compatibility, torque specifications, or require assistance with a specific application scenario, our experts are just a call or email away. We also offer detailed technical documentation, including product specifications, material data sheets, and installation advisories, to empower your technicians with the information they need for efficient and effective repairs. Our delivery logistics are optimized for speed and reliability, recognizing that vehicle downtime directly impacts your bottom line. We maintain robust inventory levels of the Full Gasket Set 04111-28133 00140 TOYOTA 2AZ to facilitate prompt order fulfillment and utilize a network of trusted global shipping partners to ensure your components arrive safely and on time, anywhere in the world. For large fleet operators or remanufacturing facilities, we can collaborate on customized supply chain solutions, including consignment inventory or just-in-time delivery models, to streamline your procurement process and enhance operational efficiency. This holistic approach to product quality, comprehensive support, and efficient logistics underscores our dedication to being a trusted and valuable partner in your business operations, contributing directly to the longevity and reliability of every Toyota 2AZ engine you service.

The `Full Gasket Set 04111-28133 00140 TOYOTA 2AZ` represents a critical investment in the long-term health and efficiency of Toyota 2AZ engines. Its meticulous engineering, adherence to rigorous quality standards, and selection of advanced materials ensure superior sealing performance, contributing directly to optimal engine compression, minimal fluid leakage, and extended operational lifespan. Beyond simply providing a replacement part, we offer a solution underpinned by deep technical expertise, extensive real-world experience, verifiable authoritative certifications, and an unwavering commitment to trustworthiness through comprehensive support and warranty. As automotive technology continues to evolve, the demands on engine sealing components will only intensify, driven by trends toward higher efficiency, stricter emissions regulations, and the integration of new propulsion technologies. The future of automotive sealing will likely see further advancements in smart materials capable of adapting to dynamic engine conditions, enhanced coatings for improved friction reduction and sealing integrity, and sustainable manufacturing practices that minimize environmental impact. The transition towards electrification, while reducing the overall demand for traditional internal combustion engine gaskets, will introduce new sealing challenges in battery packs, electric motors, and thermal management systems for electric vehicles, necessitating innovative solutions from the gasket industry. However, for the foreseeable future, the vast installed base of internal combustion engines, including the robust Toyota 2AZ, will continue to rely on high-performance gasket sets for their ongoing maintenance and longevity. Our continuous investment in R&D and our commitment to adapting to these evolving industry needs position us to remain at the forefront of automotive sealing solutions, ensuring that our products, including the `Full Gasket Set 04111-28133 00140 TOYOTA 2AZ`, continue to meet and exceed the expectations of a demanding global market.