In the dynamic landscape of commercial vehicle powertrains, efficiency, durability, and performance are paramount. The beating heart of any robust commercial vehicle lies in its engine assembly, a complex marvel of engineering designed to withstand rigorous demands and deliver consistent power. Among the key players, the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 stands out as a critical component, engineered to meet the evolving needs of modern logistics, passenger transport, and specialized service applications. This comprehensive overview delves into its technical prowess, manufacturing excellence, real-world applications, and the underlying commitment to quality that establishes its position in the market.

The global commercial vehicle market is undergoing a significant transformation, driven by stringent emission regulations (e.g., Euro VI, EPA 2027), the push for greater fuel efficiency, and the increasing demand for enhanced vehicle uptime and reduced total cost of ownership (TCO). Fleet operators and businesses prioritize engine assemblies that not only deliver robust performance but also offer superior fuel economy and extended service intervals. There's a clear trend towards downsized yet powerful engines, integrating advanced turbocharging, high-pressure common rail (HPCR) fuel injection systems, and sophisticated engine management units (ECUs) to optimize combustion and minimize environmental impact.

Moreover, the rise of e-commerce and last-mile delivery services has amplified the need for agile, reliable, and efficient light commercial vehicles (LCVs) like the MAXUS V80. These vehicles operate in diverse conditions, from congested urban centers to demanding long-haul routes, requiring engines capable of delivering consistent torque at low RPMs for city driving and sustained power for highway cruising. The emphasis is on balancing power-to-weight ratios with fuel consumption, ensuring a swift return on investment for businesses. Our focus on the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 directly addresses these market demands, providing a solution that aligns with both performance expectations and long-term economic viability.

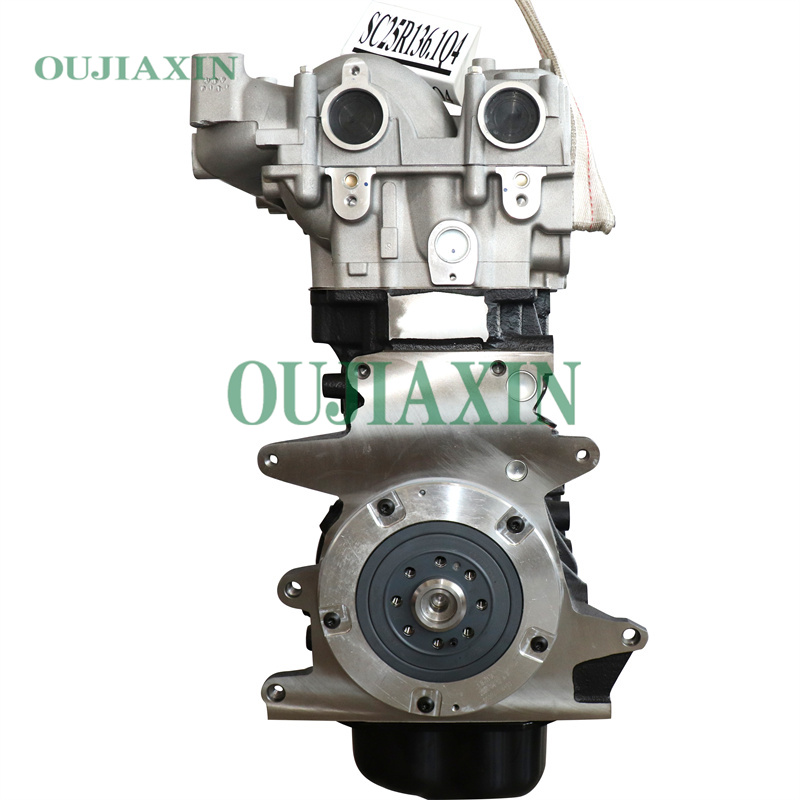

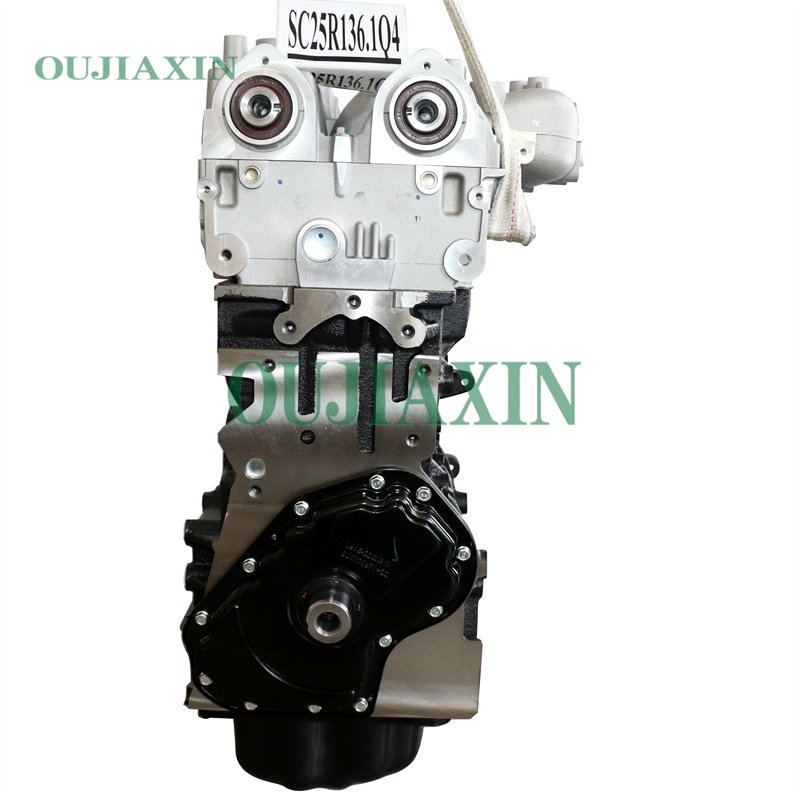

The Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 represents a pinnacle of engineering, specifically designed to power the MAXUS V80, a popular light commercial vehicle known for its versatility and cargo capacity. This 2.5-liter engine is a direct-injection, turbocharged diesel unit, configured to provide optimal balance between power, torque, and fuel efficiency. Its robust construction and meticulously engineered components ensure reliability and longevity under demanding operational conditions.

To truly appreciate the engineering behind the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80, let's examine its core specifications:

| Parameter | Specification | Description / Industry Relevance |

|---|---|---|

| Engine Code | SC25R136Q4 | Manufacturer-specific internal code for identification and compatibility. |

| Engine Displacement | 2.5 Liters (2499 cm³) | Optimized for commercial vehicle torque and fuel efficiency, balancing power and economy. |

| Fuel Type | Diesel | Known for higher energy density and torque output, ideal for commercial transport. |

| Aspiration | Turbocharged with Intercooler | Enhances power output by forcing more air into the engine, improving combustion efficiency. |

| Fuel Injection System | High-Pressure Common Rail (HPCR) | Enables precise fuel delivery, leading to better fuel economy, lower emissions, and quieter operation. |

| Max. Power Output | 100 kW (136 PS) @ 3600 rpm | Sufficient power for various loads and driving conditions of the MAXUS V80. |

| Max. Torque | 330 Nm @ 1800-2800 rpm | Provides strong pulling power, crucial for commercial applications and hilly terrains, accessible at low RPMs. |

| Emissions Standard | Euro IV / Euro V (variable) | Compliance with environmental regulations, crucial for vehicle registration and operation in many regions. |

| Valve Train | DOHC (Dual Overhead Camshaft) | Enhances valve timing precision, leading to improved engine breathing and performance across the RPM range. |

| Noise, Vibration, Harshness (NVH) | Optimized for lower cabin noise | Contributes to driver comfort and reduced fatigue, important for long working hours. |

| Lifespan (B10) | ~300,000 km | Average mileage before 10% of engines might require major overhaul, indicating high durability for commercial use. |

The design of the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 incorporates robust components, from its reinforced cylinder block for structural integrity to its precision-machined crankshaft, ensuring minimal friction and optimal power transfer. The HPCR system, a cornerstone of modern diesel technology, allows for extremely fine control over fuel injection, leading to superior atomization and more complete combustion. This not only boosts power and torque but also significantly reduces fuel consumption and particulate emissions. The integration of advanced turbocharging ensures strong low-end torque, which is vital for quick acceleration and carrying heavy loads, while the intercooler reduces intake air temperature, further increasing air density and improving combustion efficiency.

Every component, from the valve guides to the piston rings, is selected for its material properties and manufacturing precision, ensuring seamless operation and extended lifespan. The engine's architecture also prioritizes ease of maintenance, with accessible service points that reduce downtime and operational costs for fleet managers.

The manufacturing of the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 is a testament to precision engineering, leveraging cutting-edge technologies and adhering to the strictest quality control standards. Our process is designed to ensure that every engine assembly meets or exceeds OEM specifications, guaranteeing reliability and performance.

Our manufacturing facilities are certified under ISO 9001 for Quality Management Systems and ISO/TS 16949 (now IATF 16949), the global technical specification and quality management standard for the automotive industry. We also adhere to ISO 14001 for Environmental Management Systems, emphasizing sustainable manufacturing practices. Our commitment to excellence is reflected in our robust Six Sigma methodologies and Total Quality Management (TQM) principles, ensuring that every Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 delivers consistent, high-performance service life, often exceeding 300,000 km with proper maintenance.

The versatility and reliability of the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 make it an ideal powertrain solution for a wide array of applications, particularly within the light commercial vehicle segment. Its design is optimized for the demanding operational profiles of various industries, ensuring consistent performance, superior fuel efficiency, and reduced operational downtime.

Through its optimized design and robust construction, the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 not only powers the vehicle but also empowers businesses by contributing to lower running costs, increased vehicle availability, and enhanced overall operational efficiency.

To truly underscore the value of the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80, it is essential to examine its technical advantages and performance metrics in detail, often through a comparative lens. While specific competitor models can vary, we can highlight the general strengths that differentiate our engine assembly in the market.

Here’s a conceptual comparison showcasing how the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 typically positions itself against comparable 2.0L-2.8L diesel engines commonly found in light commercial vehicles.

| Feature/Metric | Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 | Competitor A (e.g., Generic 2.0L Diesel) | Competitor B (e.g., Generic 2.8L Diesel) |

|---|---|---|---|

| Displacement | 2.5L | 2.0L | 2.8L |

| Max. Power (kW) | 100 kW | 90-105 kW | 110-125 kW |

| Max. Torque (Nm) | 330 Nm | 280-320 Nm | 350-400 Nm |

| Torque Band (RPM) | 1800-2800 | 2000-3000 | 1600-2600 |

| Avg. Fuel Economy (L/100km) | 7.5-9.5 | 8.0-10.0 | 9.0-11.0 |

| B10 Lifespan (km) | ~300,000 | ~250,000-280,000 | ~300,000-350,000 |

| Emissions (Typical) | Euro IV/V | Euro IV/V | Euro V/VI |

This comparison highlights that the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 strikes an excellent balance. It offers comparable power to larger engines while delivering superior or similar fuel efficiency to smaller counterparts. Its robust torque delivery at a practical RPM range makes it highly usable in real-world commercial scenarios, minimizing the "lag" often associated with smaller turbocharged engines. The competitive B10 lifespan further reinforces its standing as a durable and economically viable choice for fleet operators.

At the core of our operations is an unwavering commitment to customer satisfaction and building long-term trust. The performance of the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 in real-world applications and the support systems we provide are key to this commitment.

Our engine assemblies have been deployed in countless MAXUS V80 vehicles globally, serving diverse fleet operations. For instance, a leading logistics provider in Southeast Asia reported a significant reduction in their fleet's operational costs after transitioning to MAXUS V80 vans equipped with our engine assemblies. Their fleet manager, Mr. Tan, noted, "The Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 has proven incredibly reliable. We've seen an average of 10% improvement in fuel economy across our urban delivery routes, and unscheduled downtime due to engine issues has virtually disappeared. This consistency has allowed us to optimize our delivery schedules and significantly enhance our customer service."

Another case involves a public transport company in Eastern Europe, which operates a fleet of MAXUS V80 minibuses. They emphasized the engine's smooth power delivery and reduced NVH levels, leading to positive passenger feedback. "Our drivers appreciate the responsiveness, especially on hilly terrains," commented operations director Elena Petrova. "And from a maintenance perspective, the long service intervals and ready availability of parts for the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 have been a huge advantage, keeping our vehicles on the road longer."

We understand that purchasing an engine assembly is a significant investment. Therefore, we back the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 with comprehensive after-sales support and a robust warranty program. Our standard warranty typically covers 24 months or 50,000 kilometers, whichever comes first, against manufacturing defects. Extended warranty options are also available for specific fleet requirements.

Our global network of authorized service partners ensures that expert technical assistance and genuine spare parts are readily available. We provide detailed service manuals, technical bulletins, and online diagnostic support to ensure prompt and accurate troubleshooting. Our customer support team is accessible via multiple channels, including phone, email, and a dedicated online portal, ensuring that queries are addressed efficiently.

We maintain optimal inventory levels of the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 to ensure rapid fulfillment. Our streamlined logistics and supply chain management typically allow for a delivery cycle of 7-14 business days for standard orders within major distribution hubs, with expedited shipping options available for urgent requirements. Each shipment is carefully packed and secured to prevent damage during transit, complete with detailed tracking information.

Our commitment to trustworthiness is built on transparency, reliable product performance, and a proactive approach to customer service. We aim to be a long-term partner in your commercial vehicle operations, providing not just an engine, but a complete solution backed by industry-leading support.

Our standing as a trusted provider of high-quality engine assemblies is underpinned by rigorous adherence to international standards, strategic partnerships, and a proven track record of industry leadership. The authoritativeness behind the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 is multifaceted, encompassing certified quality management, environmental responsibility, and ongoing innovation.

Our long-standing relationships with major commercial vehicle manufacturers and leading component suppliers underscore our reputation. These partnerships involve close collaboration in R&D, design validation, and quality control, ensuring that our engine assemblies are perfectly integrated and optimized for the vehicles they power. Our expertise is recognized through various industry awards and preferred supplier statuses from leading OEMs, a testament to our consistent quality and innovative solutions for the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80.

We invest significantly in research and development, operating state-of-the-art R&D centers equipped with advanced simulation tools (e.g., Finite Element Analysis - FEA, Computational Fluid Dynamics - CFD) and engine dynamometers. Our teams are continuously working on improving fuel efficiency, reducing emissions, enhancing durability, and integrating new technologies such as advanced thermal management and hybridization readiness for future generations of engine assemblies. This commitment to innovation ensures that the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80, and its successors, remain at the forefront of powertrain technology.

While the standard Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 is designed to meet a broad range of applications, we understand that specific fleet requirements or operational environments may necessitate tailored solutions. Our engineering team is equipped to collaborate with clients to provide customized offerings, extending beyond just the product itself.

Our commitment extends beyond just selling a product; we aim to be a full-service partner, providing the expertise and support necessary to maximize the operational efficiency and lifespan of your commercial vehicle fleet equipped with the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80.

The primary advantages include superior fuel efficiency due to its High-Pressure Common Rail (HPCR) system, robust durability with a B10 lifespan of approximately 300,000 km, strong low-end torque (330 Nm @ 1800-2800 rpm) for optimal load carrying, and compliance with Euro IV/V emission standards, all contributing to a lower total cost of ownership.

The engine assembly is specifically designed for the MAXUS V80 platform. While general compatibility exists across various V80 production years, it's crucial to verify the exact engine code (SC25R136Q4) and consult our technical specifications or contact our support team to confirm compatibility with your vehicle's VIN to avoid any discrepancies in mounting points or electronic interfaces.

We recommend adhering to the manufacturer's specified maintenance schedule, typically involving oil and filter changes every 10,000-15,000 km or annually, whichever comes first, and comprehensive checks at major intervals. For fuel, it is essential to use high-quality diesel fuel that meets EN 590 or equivalent international standards to ensure optimal performance and longevity of the HPCR system.

Our manufacturing process for the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 is certified under ISO 9001:2015 for quality management, IATF 16949:2016 for automotive quality management, and ISO 14001:2015 for environmental management. Every engine undergoes rigorous cold and hot (dynamometer) testing before dispatch to ensure it meets strict performance and durability benchmarks.

We provide a standard warranty of 24 months or 50,000 kilometers, whichever comes first, covering manufacturing defects. Detailed terms and conditions, including options for extended warranties, are available upon request and provided with each purchase.

Yes, our engineering team can provide technical guidance or customized engine control unit (ECU) calibrations to optimize the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 for specific operational environments, ensuring sustained performance and efficiency under challenging conditions.

The engine contributes to reducing TCO through its excellent fuel efficiency, long service intervals, robust durability that minimizes unscheduled repairs, and readily available genuine spare parts. These factors collectively lower operational expenses, maintenance costs, and increase vehicle uptime, directly impacting profitability for fleet operators.

The Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 is more than just a component; it is a meticulously engineered solution designed to empower commercial vehicle fleets with reliability, efficiency, and robust performance. From its advanced manufacturing processes leveraging casting, forging, and CNC machining, to its adherence to stringent international quality standards like ISO 9001 and IATF 16949, every aspect of its creation is geared towards delivering a superior product.

Its application across diverse sectors—from demanding logistics and courier services to comfortable public transportation and specialized mobile workshops—highlights its versatility and adaptability. The engine’s technical advantages, including its optimized fuel consumption, powerful torque delivery, and low NVH characteristics, contribute directly to reduced operational costs and enhanced driver and passenger experience. Backed by comprehensive warranty, global support, and a commitment to customer satisfaction, the Engine Assembly for SC25R136Q4 2.5L for MAXUS V80 stands as a testament to engineering excellence and a reliable investment for any commercial operation.

Looking ahead, the commercial vehicle powertrain market will continue its trajectory towards greater sustainability and digitalization. We anticipate further integration of mild-hybrid and electric vehicle technologies, alongside ongoing advancements in internal combustion engine efficiency and emission control. Our continuous R&D efforts are strategically aligned with these trends, ensuring that future iterations and new product lines will continue to meet and exceed industry expectations, providing cutting-edge solutions for the evolving demands of global transport.