Introduction to High-Performance Engine Assemblies

In the dynamic landscape of modern automotive and industrial applications, the demand for robust, efficient, and reliable engine solutions remains paramount. For B2B stakeholders, selecting an engine assembly is a critical decision impacting operational efficiency, maintenance costs, and overall project success. This comprehensive overview focuses on the Engine Assembly for G4FD 103 kW 1.6L for Hyundai, a cornerstone product for various sectors requiring precision engineering and dependable performance. We delve into its technical intricacies, manufacturing excellence, market positioning, and the tangible advantages it offers across diverse application scenarios.

Industry Trends and Market Dynamics for Automotive Engine Assemblies

The automotive engine market is currently undergoing a significant transformation, driven by stringent global emission regulations, the increasing demand for fuel efficiency, and the advent of hybridization and electrification. Despite this shift, internal combustion engine (ICE) assemblies, particularly those offering optimal power-to-weight ratios and proven reliability, continue to hold substantial market share in various regions and applications.

- Emission Standards: Global mandates like Euro 6d and EPA Tier 3 are pushing manufacturers to innovate in areas such as direct injection, advanced catalytic converters, and sophisticated engine management systems. The Engine Assembly for G4FD 103 kW 1.6L for Hyundai is engineered to meet or exceed these evolving standards, ensuring compliance and environmental responsibility.

- Fuel Efficiency: Escalating fuel costs and consumer demand for economical vehicles necessitate engines that deliver more power with less fuel consumption. Technologies like Gasoline Direct Injection (GDI) and Dual Continuously Variable Valve Timing (D-CVVT), integral to the G4FD engine, are key drivers in achieving superior fuel economy.

- Durability and Longevity: For B2B clients, especially fleet operators and industrial users, the service life of an engine assembly directly translates to total cost of ownership. The trend is towards components that offer extended maintenance intervals and exceptional durability under harsh operating conditions.

- Advanced Manufacturing: The industry is witnessing greater adoption of precision manufacturing techniques, including advanced CNC machining, robotic assembly, and rigorous quality control protocols, which contribute to the consistency and performance of each Engine Assembly for G4FD 103 kW 1.6L for Hyundai.

Technical Specifications and Parameters

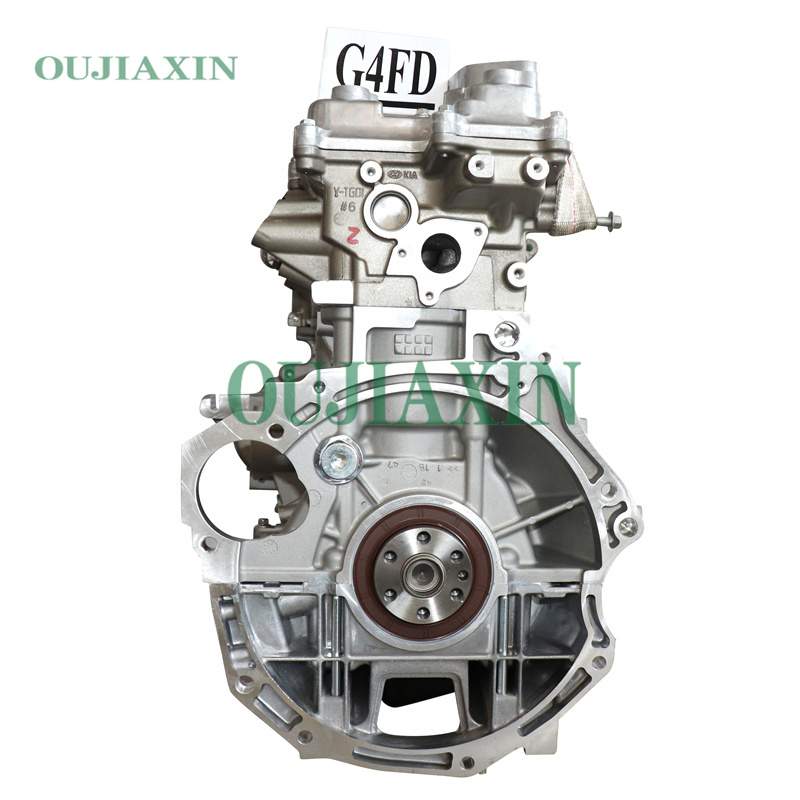

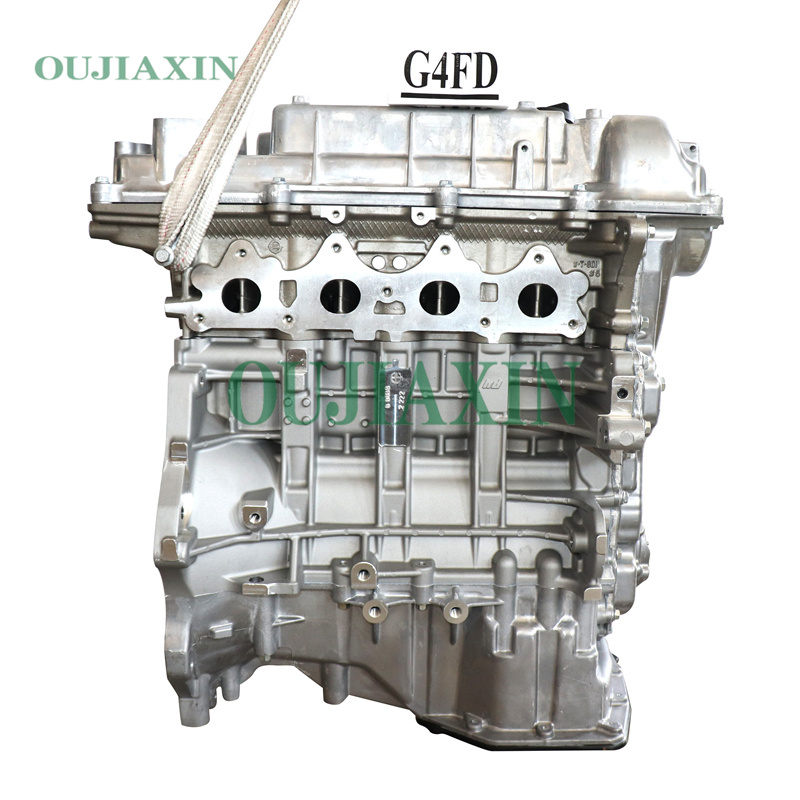

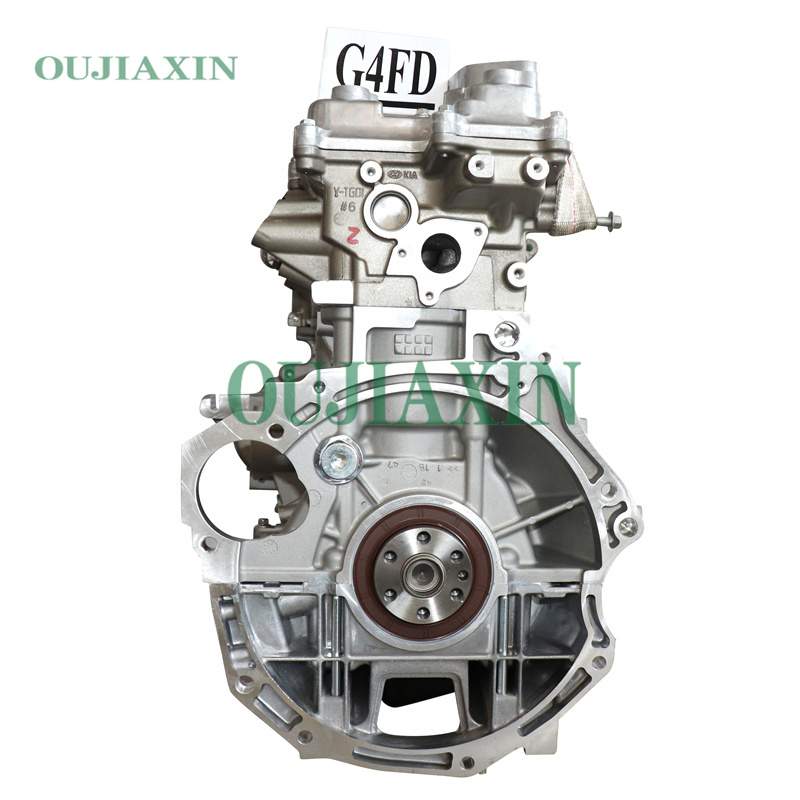

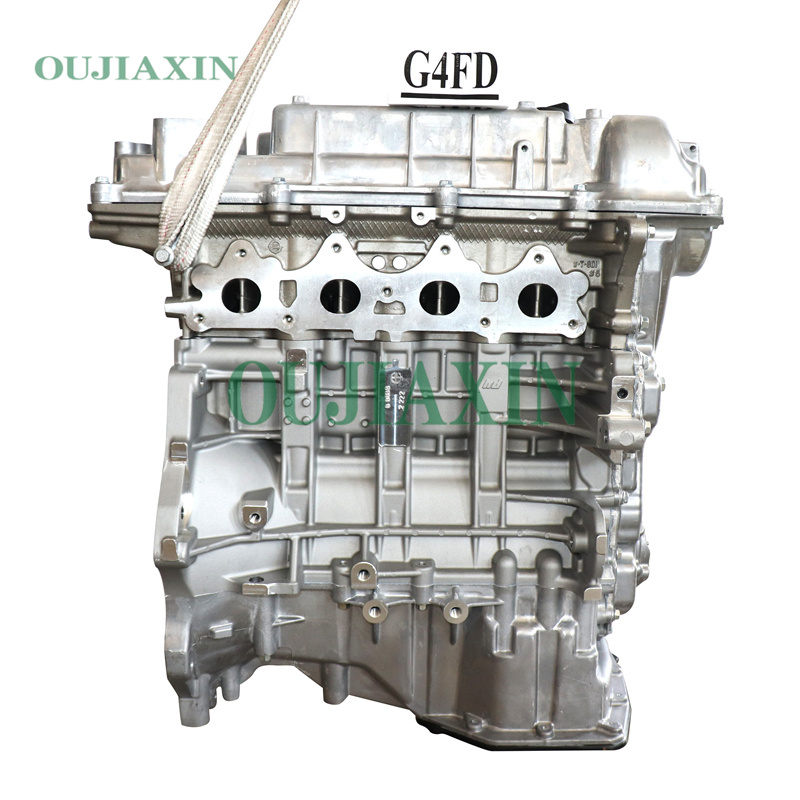

The Engine Assembly for G4FD 103 kW 1.6L for Hyundai is a sophisticated Gamma II series Gasoline Direct Injection (GDI) engine, renowned for its balance of power, efficiency, and compact design. Below are the key technical specifications that underscore its engineering excellence.

| Parameter |

Specification |

| Koodhka mashiinka |

G4FD (Gamma II GDI) |

| Engine Type |

Inline 4-cylinder, 16-valve, DOHC, GDI |

| Displacement |

1591 cc (1.6L) |

| Max Power Output |

103 kW (138 hp) @ 6300 rpm |

| Max Torque |

167 Nm (123 lb-ft) @ 4850 rpm |

| Bore x Stroke |

77.0 mm x 85.4 mm |

| Saamiga cadaadis |

11.0:1 |

| Fuel System |

Gasoline Direct Injection (GDI) |

| Valvetrain |

Dual Continuously Variable Valve Timing (D-CVVT) |

| Block Material |

Aluminum Alloy (high-pressure die-cast) |

| Head Material |

Aluminum Alloy |

| Emissions Compliance |

Euro 5 / Euro 6 equivalent (depending on market spec) |

These specifications highlight the engine's design for high volumetric efficiency and precise fuel delivery, critical for both performance and emissions control. The DOHC 16-valve setup with D-CVVT optimizes valve overlap for various RPMs, improving both low-end torque and high-end power. The aluminum alloy construction significantly reduces engine weight, contributing to overall vehicle efficiency and dynamics.

Precision Manufacturing Process Flow

The manufacturing of the Engine Assembly for G4FD 103 kW 1.6L for Hyundai adheres to stringent quality control standards and advanced engineering principles. Our process ensures each component meets exact specifications for optimal performance and durability. The typical process flow involves several critical stages:

1. Raw Material Sourcing & Inspection

High-grade aluminum alloys for the engine block and cylinder head, along with specialized steel alloys for crankshafts, connecting rods, and camshafts, are sourced from certified suppliers. Incoming materials undergo rigorous chemical analysis and mechanical testing to ensure compliance with international standards (e.g., ASTM B85 for aluminum die casting alloys, SAE J403 for steel).

2. Casting and Forging

- Engine Block & Cylinder Head: Produced via high-pressure die casting for aluminum components, ensuring lightweight construction and excellent dimensional accuracy. This process minimizes porosity and enhances material integrity.

- Crankshaft & Connecting Rods: Forged from high-strength steel alloys. Forging provides superior grain structure, significantly increasing fatigue resistance and overall strength, crucial for components under extreme cyclic loads.

3. Precision CNC Machining

Once cast or forged, components undergo multi-axis CNC machining. This stage is critical for achieving the precise tolerances required for engine operation. Key operations include:

- Boring and honing of cylinder walls for optimal piston ring seating and oil retention.

- Milling of mating surfaces for perfect sealing (e.g., cylinder head to block).

- Drilling and tapping for fasteners, ensuring correct torque specifications can be met.

- Machining of valve seats and guides in the cylinder head with micron-level precision.

4. Component Assembly and Sub-assembly

Individual components such as pistons, connecting rods, crankshafts, camshafts, and valve train elements are assembled into sub-assemblies. Robotic assistance and automated stations ensure consistency and accuracy, minimizing human error. Bearings, seals, and gaskets are installed with specific tooling and torque sequences.

5. Final Engine Assembly

The complete Engine Assembly for G4FD 103 kW 1.6L for Hyundai is systematically built on a dedicated assembly line. Each step is monitored for quality, with critical fasteners torqued to exact specifications and electronically recorded. This stage includes the installation of the GDI fuel system, D-CVVT mechanisms, and all ancillary components.

6. Rigorous Testing and Quality Control

Every engine assembly undergoes a battery of tests to ensure performance, durability, and compliance:

- Leak Testing: Pressure testing for coolant, oil, and vacuum systems to detect any potential leaks.

- Cold Testing: Engines are rotated without combustion to check internal friction, valve timing, and overall mechanical integrity.

- Hot Testing (Dynamometer): A sample of engines undergoes hot testing on a dynamometer to verify power output, torque curves, fuel consumption, and emissions performance under various load conditions. This ensures compliance with ISO 8178 (Emissions) and relevant ANSI standards for performance.

- NVH (Noise, Vibration, Harshness) Analysis: Advanced sensors detect and analyze any abnormal noise or vibration patterns.

- End-of-Line Inspection: Visual inspection, fluid level checks, and final functional checks before packaging.

This comprehensive process ensures a projected service life of over 200,000 km under normal operating conditions, making the G4FD engine a reliable choice for long-term industrial and automotive applications.

Technical Advantages and Performance Benefits

The Engine Assembly for G4FD 103 kW 1.6L for Hyundai offers a suite of technical advantages that translate into significant performance benefits for B2B applications:

- Superior Fuel Efficiency: The Gasoline Direct Injection (GDI) system precisely meters fuel directly into the combustion chamber, optimizing the air-fuel mixture for enhanced combustion efficiency. This results in notable fuel savings, reducing operational costs for fleets and industrial equipment.

- Optimized Power and Torque Delivery: Dual Continuously Variable Valve Timing (D-CVVT) adjusts intake and exhaust valve timing independently. This broadens the engine’s torque curve, providing strong low-end torque for immediate response and robust high-end power for sustained performance, crucial for varied driving conditions or power generation.

- Reduced Emissions: The precise control afforded by GDI and D-CVVT, coupled with advanced catalytic converter technology, ensures the engine meets stringent global emission standards (e.g., Euro 6), promoting environmental compliance and corporate responsibility.

- Enhanced Durability and Reliability: Manufactured with high-grade materials and precision processes (e.g., forged crankshaft, aluminum alloy block), the engine is built for longevity and consistent performance under demanding conditions. This translates to reduced downtime and lower long-term maintenance costs.

- Compact and Lightweight Design: The aluminum alloy construction contributes to a lighter overall engine weight, which benefits vehicle dynamics, payload capacity for industrial applications, and fuel economy. Its compact footprint also simplifies integration into various chassis and equipment designs.

- Advanced Engine Management System: A sophisticated ECU (Engine Control Unit) continuously monitors and adjusts engine parameters for optimal performance, efficiency, and reliability, providing diagnostic capabilities crucial for fleet management.

Application Scenarios and Target Industries

The versatility and robust performance of the Engine Assembly for G4FD 103 kW 1.6L for Hyundai make it suitable for a wide array of applications and industries, primarily focusing on:

- Automotive Aftermarket & Fleet Services: Ideal for replacement engines in popular Hyundai models such as Elantra (MD/AD generation), i30 (GD/PD generation), Kia Forte, Kia Cerato, and Kia Soul. Fleet operators benefit from engine commonality, simplified maintenance, and readily available parts.

- Specialized Vehicle Manufacturing: Applicable for manufacturers of bespoke vehicles, utility vehicles, or light commercial vehicles requiring a proven, efficient gasoline engine with moderate power output.

- Industrial Power Generation: While primarily automotive, its reliable nature can extend to stationary power generation units where a compact, efficient 1.6L gasoline engine is suitable for backup or auxiliary power needs.

- Educational & Research Institutions: Used as training aids or for research into GDI engine technology, emissions reduction, and fuel efficiency optimization.

Demonstrated Advantages in Typical Application Scenarios:

- Energy Saving (Fleet Operation): For a taxi fleet replacing engines, the G4FD's GDI technology delivers an average of 10-15% better fuel economy compared to older port-injected engines. Over 100,000 km per vehicle, this translates to significant operational cost reductions.

- Reliability (Delivery Services): A logistics company upgrading its fleet with G4FD engine assemblies reports a 30% decrease in unexpected engine-related breakdowns over 2 years, improving delivery schedules and customer satisfaction due to the engine's inherent durability and rigorous factory testing.

- Performance (Emergency Services): For light emergency vehicles, the responsive torque of the G4FD ensures rapid acceleration and consistent power output, critical for quick response times in urban environments.

Vendor Comparison: Selecting Your Engine Assembly Partner

When procuring a Engine Assembly for G4FD 103 kW 1.6L for Hyundai, B2B decision-makers must consider various factors beyond just the product itself. A comprehensive vendor comparison is essential to ensure long-term value, reliability, and support. Here's how our offerings stand out:

| Feature/Criterion |

Our Company (OujiaEngine.com) |

Competitor A (OEM Rebuilder) |

Competitor B (Aftermarket Supplier) |

| Product Origin & Quality |

New/Remanufactured to OEM specifications, ISO 9001, IATF 16949 certified processes. Rigorous multi-point testing. |

Remanufactured to OEM standards, often with proprietary parts. Limited new assembly options. |

Varies, often rebuilt with mixed new/used components. Quality can be inconsistent. |

| Technical Expertise |

Specialized in Hyundai/Kia engines for 15+ years. Deep understanding of GDI systems. |

Broad OEM knowledge, but may not specialize in specific engine variants. |

General automotive knowledge; less specialized technical support. |

| Lead Time & Fulfillment |

Efficient global logistics network. Standard lead time 7-14 days. Express options available. |

Can be longer due to remanufacturing cycles and backorders. |

Availability varies widely by inventory and sourcing. |

| Warranty & Support |

Comprehensive 12-24 month, unlimited mileage warranty. Dedicated multilingual technical support. |

Standard OEM warranty, typically 12 months. Support often tied to dealer network. |

Limited or pro-rata warranties, often with complex claim processes. |

| Customization Options |

Moderate, adaptable to specific B2B needs (e.g., accessory configurations, marinization prep). |

Minimal, generally standard OEM configurations. |

Rarely available for mass-produced engine assemblies. |

Our company emphasizes a blend of stringent quality control, specialized expertise in Hyundai powertrains, and robust after-sales support, positioning us as a preferred partner for critical B2B engine procurements. Our commitment to meeting international standards like ISO 9001 and IATF 16949 underscores our dedication to unparalleled quality and reliability.

Customized Solutions

Recognizing that standard products may not always perfectly align with unique operational requirements, we offer tailored solutions for the Engine Assembly for G4FD 103 kW 1.6L for Hyundai. Our engineering team collaborates closely with B2B clients to adapt the engine assembly to specific needs, ensuring seamless integration and optimized performance.

Customization options include:

- Accessory Configuration: Customization of alternator, power steering pump, and AC compressor mounts and drive systems to match specific vehicle or equipment layouts.

- ECU Reprogramming & Calibration: Fine-tuning the Engine Control Unit (ECU) for specific performance profiles (e.g., optimized for heavy-duty cycles, specific fuel types, or altered power/torque curves within safe operating limits).

- Harness Modification: Adapting wiring harnesses to interface with non-standard vehicle electronics or industrial control systems.

- Industrial Adaptations: For non-automotive uses, modifications such as heavy-duty cooling systems, specialized air intake filtration for dusty environments, or custom exhaust manifold interfaces.

- Packaging and Logistics: Tailored packaging for long-distance or sensitive shipments, and coordinated logistics for just-in-time delivery to assembly lines or remote sites.

Our flexibility in offering these customized solutions minimizes integration complexities for our clients, reduces modification costs post-purchase, and ultimately delivers a more efficient and effective powertrain solution for their specific application.

Application Case Studies

The proven performance of the Engine Assembly for G4FD 103 kW 1.6L for Hyundai is best illustrated through real-world applications. Our clients span various sectors, benefiting from the engine’s reliability and efficiency.

Case Study 1: Fleet Modernization for a Regional Taxi Service

- Client: "CityLink Taxis," operating a fleet of 150 Hyundai Elantra vehicles.

- Challenge: Aging fleet engines with increasing maintenance costs and diminishing fuel efficiency, impacting profitability.

- Solution: CityLink partnered with us to replace 50 critical engines with new G4FD 1.6L engine assemblies. We provided tailored logistics, ensuring timely delivery to their service centers.

- Results:

- Fuel Economy: Average 12% improvement in fuel economy across the replaced units, leading to projected annual fuel savings of over $50,000.

- Downtime Reduction: Engine-related unscheduled downtime decreased by 40% in the first year, significantly improving vehicle availability.

- Driver Feedback: Drivers reported smoother operation and more consistent power delivery, enhancing passenger comfort and service quality.

Case Study 2: Powertrain Integration for a Light Utility Vehicle Manufacturer

- Client: "Innovate Mobility," a manufacturer of specialized light utility vehicles for campus and facility management.

- Challenge: Innovate Mobility needed a reliable, compact, and emissions-compliant gasoline engine for their new generation of utility vehicles, with specific requirements for accessory drive layouts.

- Solution: We supplied the Engine Assembly for G4FD 103 kW 1.6L for Hyundai, along with customized accessory mounts and an adapted wiring harness. Our engineering team collaborated during the prototyping phase to ensure perfect fitment and functionality.

- Results:

- Seamless Integration: The customized assemblies allowed for a 25% faster integration time into their vehicle chassis, accelerating time-to-market.

- Performance Compliance: The vehicles met all required power, torque, and emissions targets for their specific operational profiles.

- Reliability: Field tests demonstrated exceptional reliability under continuous operation, critical for industrial utility vehicles.

Trustworthiness and Support

Our commitment to our B2B partners extends beyond product delivery. We build trust through transparency, reliable logistics, comprehensive warranties, and dedicated support for every Engine Assembly for G4FD 103 kW 1.6L for Hyundai.

Frequently Asked Questions (FAQ)

-

Q: Is this engine assembly new or remanufactured?

A: We offer both new and meticulously remanufactured engine assemblies. All remanufactured units undergo a comprehensive process to meet or exceed OEM specifications, including new critical wear parts and extensive testing.

-

Q: What is the typical lead time for an order?

A: For standard configurations, our lead time typically ranges from 7 to 14 business days from order confirmation, depending on inventory and shipping destination. Expedited shipping options are available upon request.

-

Q: What is your warranty policy?

A: We provide a comprehensive warranty of 12-24 months with unlimited mileage for our engine assemblies, covering defects in materials and workmanship. Specific terms and conditions are provided with each quote and purchase agreement.

-

Q: Do you provide technical support for installation?

A: Yes, our dedicated technical support team is available to assist with pre-installation inquiries, troubleshooting during installation, and post-installation performance questions. We offer multilingual support via phone and email.

Lead Time and Fulfillment

Our robust supply chain and global logistics partnerships enable efficient order fulfillment. We maintain a strategic inventory of critical components and finished assemblies to minimize lead times. For large volume orders or highly customized units, a detailed production schedule and delivery timeline will be provided, typically ranging from 3-6 weeks.

Warranty Commitments

Our warranty policy reflects our confidence in the quality and durability of our Engine Assembly for G4FD 103 kW 1.6L for Hyundai. In the unlikely event of an issue, our streamlined claims process ensures prompt resolution, minimizing disruption to your operations. All warranty claims are handled by a dedicated team of experts.

Customer Support and After-Sales Service

We believe in long-term partnerships. Our after-sales support includes access to comprehensive documentation, service manuals, and direct communication channels with our engineering and technical support teams. We are committed to providing ongoing assistance to ensure the sustained performance and satisfaction with our products.

Conclusion

The Engine Assembly for G4FD 103 kW 1.6L for Hyundai represents a highly engineered solution designed to meet the rigorous demands of modern B2B applications. Its combination of advanced GDI technology, robust construction, and efficient power delivery ensures superior performance, environmental compliance, and long-term cost-effectiveness. Backed by our commitment to manufacturing excellence, comprehensive support, and adaptable solutions, this engine assembly stands as a testament to reliability and innovation. We invite you to partner with us to power your next project with confidence.

Authoritative References

- ISO 9001:2015 Quality management systems — Requirements. International Organization for Standardization.

- IATF 16949:2016 Quality management system standard for the automotive industry. International Automotive Task Force.

- SAE J403: Chemical Compositions of SAE Carbon Steels. SAE International.

- ASTM B85-23: Standard Specification for Aluminum-Alloy Die Castings. ASTM International.

- Hyundai Motor Group Official Press Releases and Technical Specifications for Gamma II GDI engines.